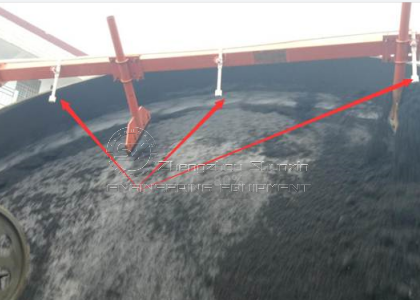

The pan grnaulator is an important fertilizer pellets making machine. When producing the granular organic fertilizer or the compound one, you can use the plate pellet making machine. For improving the granulating efficiency, FPC designs a high-quality pan granulator. There are many structural and technical advantages of the FPC disc granulation machine. When you are purchasing the granulating machine, we recommend the FPC pan granulation machine. After choosing us, you will experience many first-class service like technical support. From the following, you can know more about the FPC pan granulation machine.

How does the disc granulator machine work for fertilizer pellets production?

While using the fertilizer disc granulator, there are four granulation steps. They are materials adding, fertilizer granulating, finished produts discharging and unquality products returning. You can learn about the specific granulating processes of disk fertilizer pelletizer from the following.

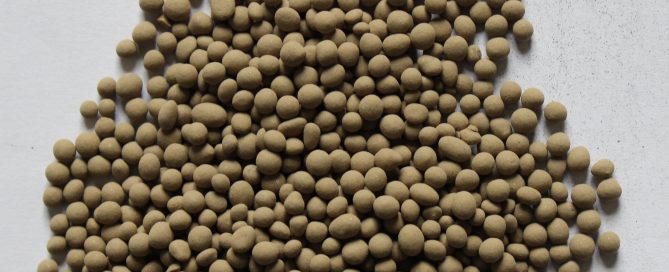

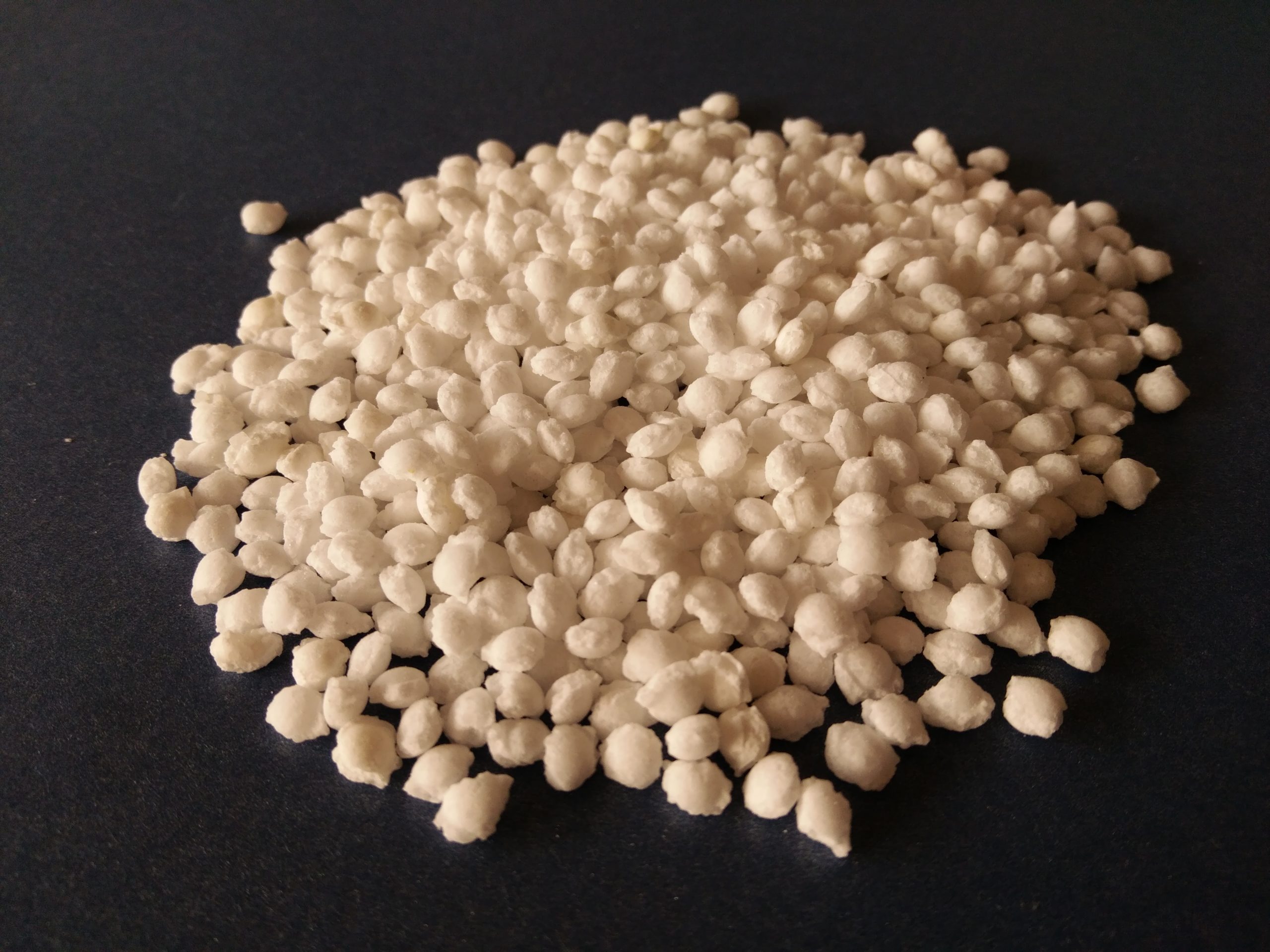

The about is four-step granulation process of disc fertilizer pelletizer. You can use it for 1-5mm fertilizer granules production. FPC produces many types of disc granulator machines. You can find an ideal fertilizer disc type granulator from us. Welcome to consultation.

Four Advanced Designs of FPC Disc Granulator Machine

From the above, you can get a futher understanding about the disc granulation process. While using disc granulator for fertilizer pellets production, you can consider FPC disc pelletizer. The disc granulation machine designed and produced by FPC company can make the fertilizer efficiently. It is related its reasonable structure. You can know about four great design points from the following.

It can be seen from the above structural characteristics that the pan granulator has a compact overall structure and the advantage of saving working area. Therefore it is an ideal equipment for organic fertilizer and compound fertilizer granulation ,and also is widely welcomed by fertilizer manufacturers.

Here are technical parameters about different models of pan granulator, such as SXYZ-500,SXYZ-1000,SXYZ-1800. The data is just for your reference.

| Model | Diameter of disc (mm) | Edge of Height(mm) | Rotary Speed(r/min) | Motor(kw) | Reduceer Model | Capacity(t/h) | Dimensions(mm) |

|---|---|---|---|---|---|---|---|

| SXYZ-500 | 500 | 200 | 32 | 0.55 | BWY0-43-0.55 | 0.02-0.05 | 650×600×800 |

| SXYZ-600 | 600 | 280 | 33.5 | 0.75 | BWY0-43-0.55 | 0.05-0.1 | 800×700×950 |

| SXYZ-800 | 800 | 200 | 21 | 1.5 | XWD4-71-1.5 | 0.1-0.2 | 900×1000×1100 |

| SXYZ-1000 | 1000 | 250 | 21 | 1.5 | XWD4-71-1.5 | 0.2-0.3 | 1200×950×1300 |

| SXYZ-1200 | 1200 | 250 | 21 | 1.5 | XWD4-71-1.5 | 0.3-0.5 | 1200×1470×1700 |

| SXYZ-1500 | 1500 | 300 | 21 | 3 | XWD5-71-3 | 0.5-0.8 | 1760×1500×1950 |

| SXYZ-1800 | 1800 | 300 | 21 | 3 | XWD5-71-3 | 0.8-1.2 | 2060×1700×2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | XWD5-71-4 | 1.2-1.5 | 2260×1650×2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | ZQ350 | 1.5-2.0 | 2900×2000×2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | ZQ350 | 2-3 | 3200×2200×3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | ZQ350 | 2-4 | 3400×2400×3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | ZQ400 | 4-6 | 4100×2900×3800 |

2 Methods To Control The Size Of Fertilizer Particles By Operating FPC Pan Granulator.

While producing the fertilizer particles, you may get the unqualified pellets. What should you do to adjust the particle size? By using FPC pan granulator, you can control the particle size to meet the production requirements. There are 2 ways to control the manure granules size.

Control The Pan Slope Angle

Because the size of the disc inclination angle of the disc granulator is also related to the size of the formed fertilizer particles. You can adjust the final granules size by controlling the pan slop angle. Generally speaking, the steeper the slope of the disk, the smaller the fertilizer particles formed by the disk granulator. On the contrary, the more gentle the disc slope, the larger the particles.

Control Moisture

The size of fertilizer granules is related to water content in the animals manure and other raw materials. So you can control the raw material moisture through controlling the water spray system. What you need to know is that lower water content in the materials , the smaller size fertilizer particles produced by pan pelletizer machine. Conversely, the more water, the bigger size.

How do you use a pan granulator efficiently in fertilizer production?

While using the pan granulating machine, you must want to make the fertilizer pellets with high efficiency. But how do you make the granulating machine work with high efficiency. Here are four tips to make your disk granulator work efficiently.

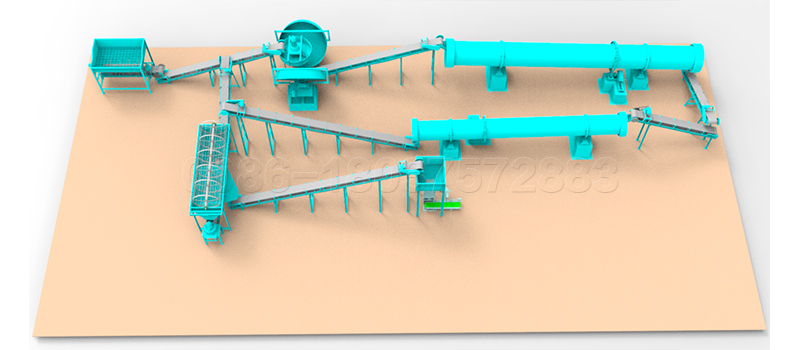

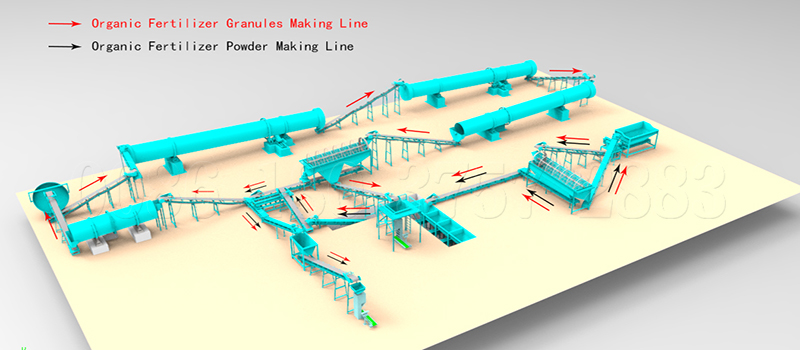

Pan Granulator for 2 Fertilizer Production Lines

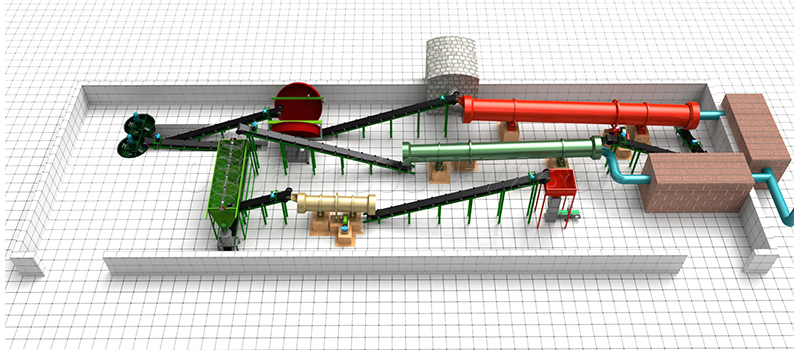

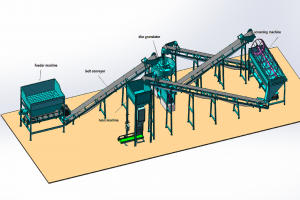

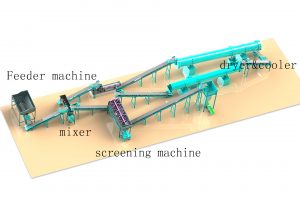

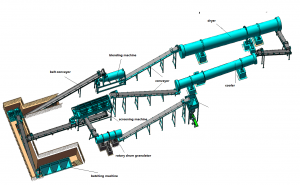

The disc granulation machine are mainly used in fertilizer production line. To meet customer’s fertilizer requirements, we research and produce two type of fertilizer disc granulation lines. One is organic fertilizer disc granulation line, and the other is compound fertilizer disc granultion line. There are 1-10 tpd disc fertilizer granules production lines for sale in FPC company. You can know these two types of fertilizer production lines from the following.

The pan granulator is an important fertilizer pellet making equipment. You can use the disc granulation machine in the organic fertilizer production lines or the compound ones. You can know more from the following.

4 Advantages of Pan Granulator in Fertilizer Production Line

Compared with other granulation, the disk granulator has many advantages in the fertilizer production. That’s why so many fertilizer manufacturers would like to use the pan pellet making machine to produce the fertilizer granules. You can learn the 4 advantages of the pan granulator from the following.

Adjustable Fertilizer Particle Size

FPC pan pelletizer has a wide control range of the fertilizer particles size. The diameter of finished fertilizer pellets you can make is 1-8mm. You can adjust the fertilizer particles size by controlling pan slop angle,rotation rates of the granulator and the moisture of the fertilizer materials.

Short Fertilizer Production Process

FPC pan granulating machine has a rapid granulation speed. Within 5-8min, you can form the powder fertilizer into particles by using plate pelletizer. Furthermore, the granulation process of the disc granulator is not very complicated. When the disk granulator works, it needs less labor. So the pan granulating machine is more suitable for medium-size and small fertilizer production factory.

High Fertilizer Production Capacity

Different specifications of pan granulators have different production capacities. The maximum fertilizer granulation capacity of FPC disc granulating machine can up to about 6 tons per hour. Our company designs different types of the pan granulator. Therefore, you can choose different specifications according to your own actual fertilizer production needs.

High Quality Of Fertilizer Particles

The surface of the fertilizer pellets produced by disc granulator are more even. And the size of the fertilizer granules granulated by the disc granulator is more uniform. In addition, the fertilizer pan granulator also has a automatic classification function for fertilizer pellets.

What Is the Price of Disc Granulator Production Line?

The price of disc granulator production line is related to its configuration and production capacity. From the above, we can know that disc fertilizer granulator can be used in organic fertilizer granules production line and compound fertilizer granulation line. These two kinds of disc granulation production lines are sold at the different prices. You can know their prices and configurations from the following.

How Much Is the Organic Fertilizer Disc Granulation Line?

The organic fertilizer disc granulation line price ranges from $110,000 to $550,000. The entire organic fertilizer pan granulation line can produce 1-20 tons of fertilizer pellets per hour. The machines needed to deploy include compost turner, crushing machine, screening machine, coating machine, disc fertilizer granulator and other fertilizer auxiliary machines. The disc granulation lines of different production capacities will be equipped with different fertilizer making machines. We can design best organic fertilizer disk granulation line based on your production needs.

How Much Does the Compound Fertilizer Pan Granulation Line Cost?

The price of compound fertilizer pan granulation line is cha. The compound fertilizer pan granulation line price is $25,000.00 – $500,000. You should buy many types of fertilizer machines to deploy whole compound fertilizer production line. For example, you need to automatic batching systems, fertilizer crusher, fertilizer disc granulator, fertilizer dryer and cooler, fertilizer coater and fertilizer packing machine. These machines from FPC company have strong adaptability. You can use them to make the NPK fertilizer, di-calcium phosphate fertilizer,ammonia fertilizer and potash fertilizer.

4 Points You Need To Pay Attention To If You Want Your Pan Granulator To Have A Long Service Life.

For reducing the cost of the production equipment, you should often note the operation situations of the pan granulation machine. Here are 4 suggestions you can refer to while using the disc pellet making machine.

Temperature

When the plate granulator works, you find that the temperature of he reducer bearing part is too high. And at the same time, there is some noise in the reducer At this moment, you need to refuel the reducer and overhaul it in time.

Stability

When the fuselage of the pan granulator runs unstably, you should pay attention to check the gap of the couplings. If it is too close, you should adjust the gap between the couplings. By doing so, you can avoid the production accidents.

Lubrication

If the temperature of the bearing at both ends of the bearing chamber is abnormally high, you have to stop machine for maintenance and add grease. Under normal conditions, you should add butter to the bearing chamber every 5-6 days.

Operation Rules

In addition, you need to pay attention to the operating rules of the disc pelletizer machine; such as: machine temperature, rotate speed, etc. According to different situations, you can timely take measures to overhaul the disc granulator.