FPC is an established fertilizer equipment production company. It has been engaged in design and production of fertilizer equipment for many years. Our machine has been sold at home and abroad. Therefore, there are many successful cases of fertilizer equipment in FPC company. Here is a case of pan granulator sold to Argentine fertilizer manufacturer customer. You can know about the detailed process from the following.

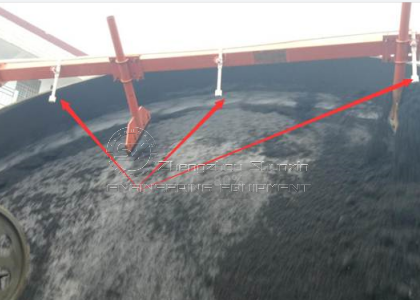

The disc pelletizer machine made form FPC company can granulate the powder materials with the size of 50 meshes. The Argentine fertilizer manufacturer customer wants to granulate the quartz sand powder. In order to make high granulate rate, we recommend the disc granulator machine for customer. FPC can recommend the suitable pellet machine for customers according to their raw materials.

When using the plate pelletizer, the customer can get the qualified fertilizer granules in 5-8minutes. You can produce 0.02-6 tons of fertilizer pellets per hour through applying the pan granulator. Because of adopting advanced granulation technology, the machine can make the fertilizer granules efficiently. This is also one of the reasons why the disc granulator is our best-selling product.

The fertilizer producer from Argentina wants to make 1mm final granules. According to his request, we recommend the disc granulator for him. The pan granulator machine from FPC company can make 1-8mm of fertilizer pellets. What’s more, you can adjust the finished granules size by regulating the added moisture and pan slope angle. You can contact us for the detailed production process of disc granulation.

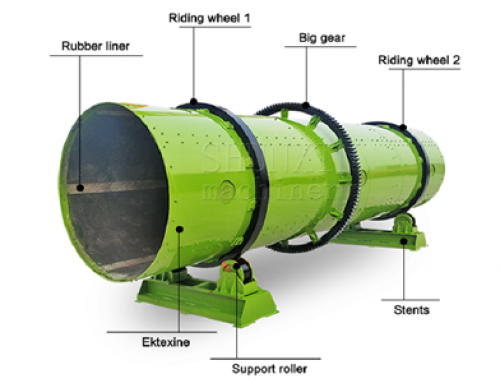

In order to storing and transporting, Argentine customer hopes to get the granulated fertilizer with less than 30% moisture. The pan granulation machine can reduce the fertilizer moisture to 20%. Therefore, it can meet the customer’s requirement. If you want to make the fertilizer granules with less than 10% moisture, the fertilizer dryer machine will be your best choice.

The disc granulation machine made from FPC company is designed for organic, inorganic, bio organic and compound fertilizer granules production. Therefore, you can use the fertilizer disc pelletizer to granulate powder organic matter. What’s more, our disc granulation machine is wildly used in NPK compound fertilizer production line and urea based compound fertilizer production line.

The disc pelletizer machine price is related to its production capacity and technical specification. You can tell us your production capacity and the amount of raw materials. We will recommend the most suitable fertilizer disc granulator for you. All of our granulator machines are on sale at the favorable price. At the promotion period, you can even get a certain discount.

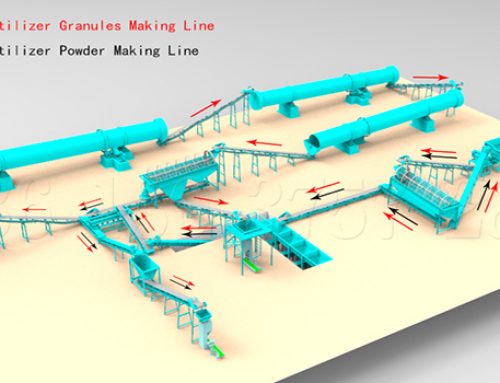

The above data is just for your reference. You can get the newest information about the disc granulator machine from us. Here are also many types of fertilizer production machines for you, such as compost turner machine, compost shredder, fertilizer granulator. You can also find complete organic fertilizer production line, compound fertilizer production line, liquid fertilizer production line in FPC company. Welcome to our website to get the detailed consultation and latest fertilizer machines quoted price.

Here are technical parameters about different models of pan granulator, such as SXYZ-500,SXYZ-1000,SXYZ-1800. The data is just for your reference.

| Model | Diameter of disc (mm) | Edge of Height(mm) | Rotary Speed(r/min) | Motor(kw) | Reduceer Model | Capacity(t/h) | Dimensions(mm) |

|---|---|---|---|---|---|---|---|

| SXYZ-500 | 500 | 200 | 32 | 0.55 | BWY0-43-0.55 | 0.02-0.05 | 650×600×800 |

| SXYZ-600 | 600 | 280 | 33.5 | 0.75 | BWY0-43-0.55 | 0.05-0.1 | 800×700×950 |

| SXYZ-800 | 800 | 200 | 21 | 1.5 | XWD4-71-1.5 | 0.1-0.2 | 900×1000×1100 |

| SXYZ-1000 | 1000 | 250 | 21 | 1.5 | XWD4-71-1.5 | 0.2-0.3 | 1200×950×1300 |

| SXYZ-1200 | 1200 | 250 | 21 | 1.5 | XWD4-71-1.5 | 0.3-0.5 | 1200×1470×1700 |

| SXYZ-1500 | 1500 | 300 | 21 | 3 | XWD5-71-3 | 0.5-0.8 | 1760×1500×1950 |

| SXYZ-1800 | 1800 | 300 | 21 | 3 | XWD5-71-3 | 0.8-1.2 | 2060×1700×2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | XWD5-71-4 | 1.2-1.5 | 2260×1650×2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | ZQ350 | 1.5-2.0 | 2900×2000×2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | ZQ350 | 2-3 | 3200×2200×3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | ZQ350 | 2-4 | 3400×2400×3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | ZQ400 | 4-6 | 4100×2900×3800 |

Leave A Comment

You must be logged in to post a comment.