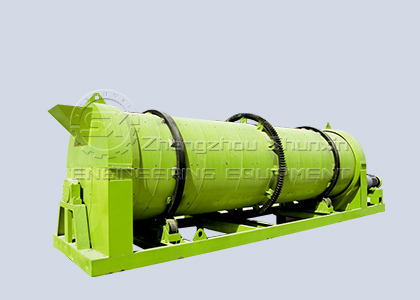

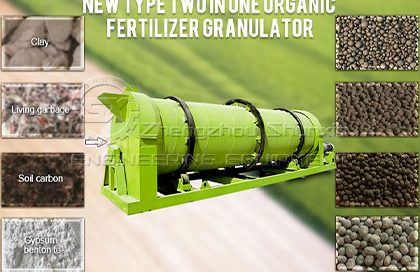

While making granular fertilizer, many fertilizer makers will use the rotary drum and churning granulator. There are two reasons for this. One is that the rotary drum churning granulation can make fertilizer particles with high density and fluidity. The other is that the rotary drum and churning granulation machine is suitable for large-scale fertilizer production plant. For getting higher working efficiency, SX improves the granulation machine structures. When granulation, the SX rotary drum churning pellet making machine will be your good choice. There are different specifications of the machine you can choose from SX. We can also give you some reasonable advice about the drum-churning granulation machine selection. In addition, we can provide you with some technical support and the first-class service. The followings are the specifications about the rotary drum and churning granulator.

Why Do You Need To Make The Fertilizer Granules With The Rotary Drum Churning Granulation Machine?

Compared with powdered fertilizers, the fertilizer granules granulated by the rotary drum and churning granulator have many advantages, such as high economic value and easy fertilization. The followings are the advantages of the fertilizer particles made by the rotary drum and churning granulation machine.

Compared with powder fertilizers, fertilizer granules granulated by the pellet fertilizer making machine will not easily become damp and agglomerate. Therefore, it is easier for you to pack,store and transport the fertilizer granules. Moreover, the fertilizer granules also facilitate mechanical fertilization.

As mentioned above, there will be uniform size of the fertilizer granules after granulated by the rotary drum and churning compound pellet making machine. Such fertilizer particles are more conducive to release the fertilizer efficiency.

After granulated by the the rotary drum and churning pellet making machine, the pellets fertilizer will not float and spread easily like powder fertilizers. Therefore, the fertilizer particles will not cause problems such as poisoning of farmers and environmental pollution.

From the above, you can know about the advantages of the pellet fertilizer made by the rotary drum and churning granulation machine. It is also precisely because of these points that many fertilizer producer would like to use the compound pellet fertilizer making machine for the granulating process.

What Are The Advantages Of The Rotary Drum Churning Granulator?

Compared with traditional granulation machines, there are many advantages of the rotary drum and churning pellet making machine. You can know about the advantages from the followings.

Because the rotary drum churning granulator overcomes many shortcomings of the traditional granulation machine, it has been widely used in the organic fertilizer manufacturing industry.

How To Choose The Right Models Of The Rotary Drum Churning Granulator?

When purchasing the rotary drum and churning granulation machine, you need to consider this from two aspects. One is your budget. The other is the production capacity. You can refer to the followings.

The Budget

Your budget determines what price and specifications of rotary drum and churning granulating machine you can buy. For example, if you want to run the granular fertilizer production lines with the budget of $190,000-$360,000, the SXZJZ-1660 rotary drum churning pellet making machine is more suitable for your fertilizer production plant.

The Production Capacity

The yield of the granular fertilizer is also closely related to the granulation machines selection. When you plan to produce 3-8 tons of fertilizer granules per hour, you can choose to use the rotary drum and churning granulator.

The parameters are for your reference only. You can choose the corresponding pellet making machine according to your actual production plan. We can also customize the pellet machines according to your requirements.

What Services Can You Experience Once You Choose The Sx Rotary Drum Churning Granulator?

If you choose the SX rotary drum churning granulation machine, you can experience the perfect service. The followings can be your reference.

We have quality records and testing data for the manufacturing and testing of our rotary drum churning pellet machine. Before selling the granulation machine, we will test its performance strictly. We also sincerely invite you to come to the site to inspect the whole process and performance of the machine. And we will pack and ship the machine after confirming that it is qualified.

Our customer service staff is available for you 24 hours a day. If you have any questions about the machine, you can contact with us. We will reply to you as soon as we receive the message.

Our service tenet is to allow customers to receive high-quality products. Therefore, in order to ensure that the product is not damaged, we will carefully pack the machine. If there is damage during transportation, we will bear the related costs.

As shown above, you can buy the SX rotary drum churning pellet making machine without any worries. We are committed to provide you with high-quality and cost-effective machine.

What Should You Notice When Using The Rotary Drum Churning Granulation Machine?

In order to make the fertilizer production more effectively and safely, you should pay attention to the following points when you operate the rotary drum and churning granulation machine.

Notice The Machine Temperature

You should check the temperature of the rotary drum and churning granulation machine at any time. If you find that some parts temperature is abnormal. You should stop using the machine to inspection at once. By doing so, you can eliminate the possibility of fertilizer production accidents.

Add The Oil In Tine

The proper lubrication is the key to normal operation of the rotary drum and churning pellet making machine. For example, if there are some noise and high temperature on the reducer bearing, you should stop and inspect the machine. At the same time, you need to add the butter into the bearing. When operating the machine normally, you should add the oil to the bearing every five days.

In addition, you should observe the machine operation law. Only in this way, you can find the fault of the machine in the first time and eliminate it in time. And you can run the granular fertilizer production lines normally. Of course, we can also offer you technical support if you need.

Through the above, you will get the further understand about the SX rotary drum and churning granulation machine. You have multiple choice in SX. What’s more, we will provide you with rotary drum and churning granulator at the best price.