FPC is an established fertilizer equipment manufacturing plant. We has been dedicated in design and production of fertilizer equipment and production line over 15years. Therefore, there are successful cases of granular fertilizer production line. Here is a case for you. You can get the detailed information from the following. In other way, you can email to us for free inquiry of other machine can production line.

Are your machines available in granulating CMS and other solid organic materials?

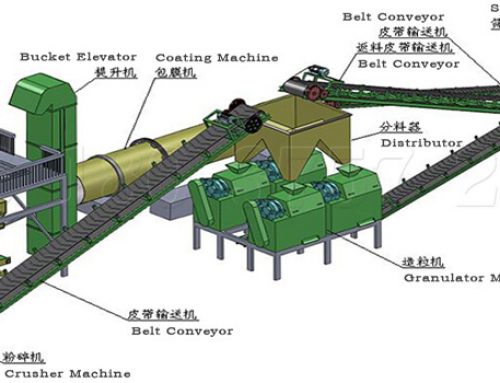

The Indonesian fertilizer manufacturer uses CMS and other solid materials like caked palm cemell, carbon, wood fiber to make the fertilizer granules. The fertilizer granulator machine made from FPC company has strong adaptability. They are widely used in organic,inorganic, compound, water soluble fertilizer production line. Therefore, the customer can use the machine to granulate CMS.

What machines can used for the most effective granulation?

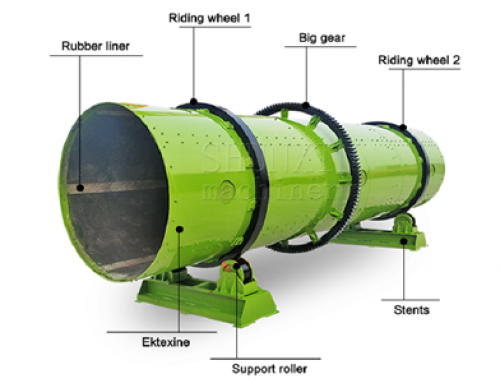

Because of low production capacity of customer’s rotary drum granulation line, he wants to buy the most effective pelletizer. According to Indonesian customer’s raw materials, we recommend the pan granulator. For each fertilizer manufacturer customer, we need to know their raw materials and production capacities. On in this way can we recommend the best model of fertilizer production machine for them.

How to treat the materials with high moisture?

The customer from Indonesia has the raw materials with moisture of 60%. Because of high moisture, it is not conducive to granulation process. Therefore, we give him some advice to lower the moisture. The customer can add wood fiber and bentonite into the raw materials. In order to mix completely, we tell the customer that he need to deploy a fertilizer mixing machine.

What other machines need I buy to build this line?

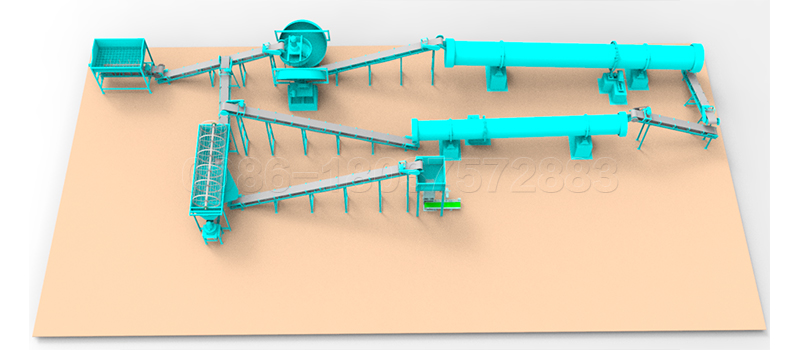

To get uniform fertilizer granules size, the screening machine is required. After granulation, the moisture and hardness of fertilizer granules don’t meet packing requirement. Therefore, the drying and cooling machine need also to be deployed. This customer’s raw materials needn’t to be fermented. We don’t recommend the organic fertilizer fermentation machine. As the experienced fertilizer equipment manufacturer, we can design different fertilizer production line based on different customers’ requirements.

What is the price of whole 3t/h granulation line?

After negotiating with the customer on the model of the equipment to be purchased, we made the latest quotation for him. The customer from Indonesia is our old customer. Therefore, we give him some discount. We will hold regular promotional activities. During the event, you can of course also enjoy satisfactory discounts. All of our fertilizer equipment are on sale at the favorable price. You can contact us for detailed consultation.

How long can I receive the fertilizer granulation line?

After signing purchase contract, our factory will produce the fertilizer making machines as soon as possible. We can finished the production mission in one month. Then, we have long-term cooperative relations with excellent domestic logistics companies. Your fertilizer production machines will be packed perfectly and delivered as fast as possible. Therefore, the customers don’t worry about the transport and receiving problems.

Can you provide corresponding technical support?

From production line design to installation, our professional technical personnel can provide you with technical assistance. In addition, we have skilled after-sale service staff. Therefore, you can not only trust the quality of our equipment, but also our service.

The above is communication process about the 3 tons/hour organic fertilizer granulation line. It is just for your reference only. Different customers has different questions and requirements. You can contact us to know more. FPC, as the established fertilizer equipment production company, there are many successful cases of fertilizer production lines. Welcome to email to us for free inquiry.

Error: Contact form not found.

Leave A Comment

You must be logged in to post a comment.