In the organic manure production industry, the fertilizer producers will consider many questions about building the organic manure production lines. Based on our years of experience, there are six problems you’d better know while managing the $45,000 organic fertilizer production line.

You will set up the relatively high-efficiency organic fertilizer production line through following the above six aspects. The advice is for your reference only. When you starting the organic manure manufacturing plant, we will provide you with different plans.

Raw Materials Selection For The $45,000 Organic Fertilizer Production Lines.

Generally speaking, there are many kinds of the raw materials that are suitable for making the organic fertilizer. However, if you want your organic manure production business to become more industrialize and commercialize, you can choose the raw materials from following two sources.

Animal Wastes

There are numerous nutrients such as nitrogen, phosphorus and potassium in animal feces, you can produce the high quality organic fertilizer by making use of the chicken manure, cow dung and other animals manures.Agricultural Wastes

Agricultural waste is often used as an auxiliary material for organic fertilizer production. You can use the agricultural waste to adjust the moisture, carbon - nitrogen ratio, and pH values in the raw material to make composting better.In addition, you’d better add some microbial species to the organic wastes while composting. By doing so, you can shorten the composting period. The composting effect will also be better.

In conclusion, no matter what raw materials you select, the following tips will give you some help.

How To Make Full Use Of The 45,000 Usd$ To Produce High Capacity Organic Fertilizer?

Generally speaking, the $45,000 powder organic fertilizer production line can make 1-5 tons of organic manure per hour. In order to improving the production yield of the organic manure, you should note the following aspects during the production process.

By noting the above four factors, you can make full use of the 45,000 USD$ to build the organic manure production line with high capacity. Moreover, you can produce the organic manure with high quality.

What Type Of Organic Fertilizer Production Line Can You Choose With 45,000 Usd$ Budget?

In production, fertiliser manufacturers will produce granular organic manure and powder one. Therefore, there are two organic fertilizer production lines you can choose from. Within $45,000, we recommend you choose the powder organic manure production line. Because the granules organic fertiliser production line needs more equipment than the powder one. In addition, powder organic fertilizer producing process is relatively simple. You will cost less to establish production line of powder organic fertilizer. Then you can get a high yield of the organic manure.

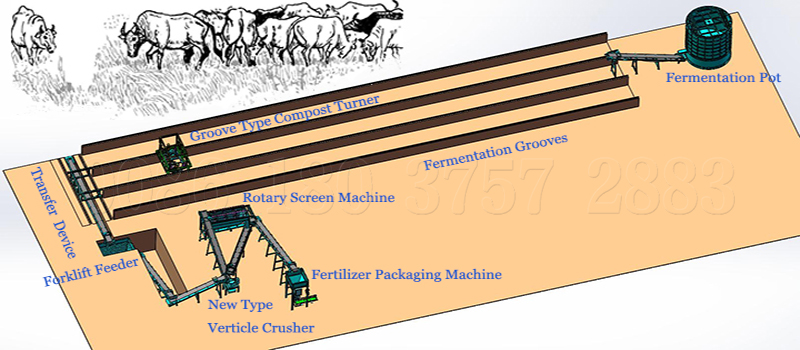

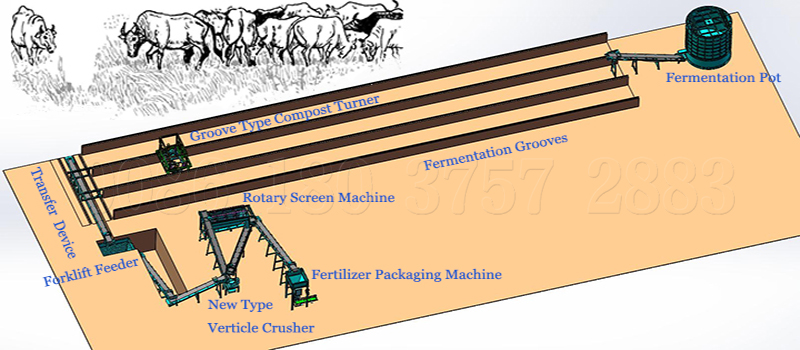

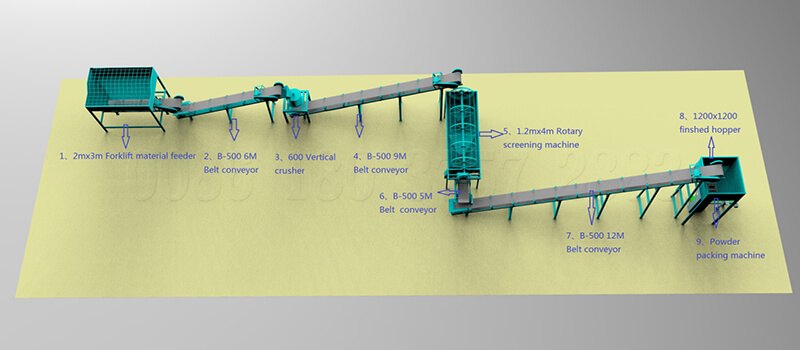

How do you design the powder organic fertiliser production line? According to the powder organic fertiliser production process, you can select the correspondent production equipment to set up the organic powder fertilizer production line. There are only four steps for the process.

As mentioned above, you should purchase the compost turner, the crusher, the screener and the packer to set up the powder organic manure production line. However, these four machines are just the main equipment for the organic manure production line. You also purchase some auxiliary machines like loader type feeder and belt conveyor to make your production line more complete. You can also consult us about designing the organic fertiliser production line. SX is a old brand fertilizer equipment production company. We can give you some reasonable advice about building the organic manure production line and choosing the production equipment.

The Production Machines For The $45,000 Organic Manure Making Plant

There are different configurations of the organic manure production equipment. The price depends on the particular configuration. For the 450,000 USD$ organic manure production line, SX can offer the following detailed equipment configurations to you.

Because the budget of the organic fertiliser production line is 450,000 USD$, there are two types of the composting machines you can purchase. The followings are the technical parameters about these two compost turners.

The Organic Fertilizer Composting Machine

In addition to the above two fertilizer composting machines, SX has other organic fertilizer compost turning machines. In SX, you can also select the wheel-type composting machine, chain plate composter and crawler type fermentation machine.

The Organic Fertilizer Crushing Machine

The new type vertical crushing machine is one of the most effective crushing machines in the organic manure equipment production market. We designed and manufactured the vertical grinders for livestock waste through our production practices. After considering, the SXFLF-600 vertical crusher is more proper for you to build the $45,000 organic manure production line.

Of course, this is for your reference only. There are different models of the organic manure shredding equipment. You can select the crushing machine according to your production plan and investment fund.

The Organic Fertilizer Rotary Screening Machine

The organic manure rotary screening machine is the special equipment for screening the materials. You can screen the 60 to 1000 tons of organic waste per hour through using the organic fertiliser rotary screening machine produced by the SX. For building the $45,000 powder organic manure production line, you can buy the SXGS-1240 rotary screening machine.

While producing, we make the organic manure screening machine with high performance. Therefore, you can maximize fertilizer production efficiency by improving screening efficiency.

The Organic Fertilizer Single Automatic Packing Equipment

For improving the bagging efficiency, there is a special packing machine for the powder organic manure. It is the single bucket automatic packing scales. You can know some information about the single bucket bagging machine.

The single bucket automatic packing machine the SX produced has the function of bagging and unloading simultaneously. Thus, you can accelerate the organic manure packing process.

While designing, we take into account the different requirements of different customers when packaging. Hence, SX single bucket automatic packing scale weighing range is from 5 kg to 50 kg.

You can choose the suitable configuration of the single bucket automatic packaging machine according to the production capacity of the $45,000 fertilizer production line. We can also provide you with customized services.

Other Support Machines For Organic Fertilizer Production

You still need some auxiliary equipment besides the above main fertilizer production machines. While composting, you’d better use the loader type feeder to transport the organic manure. Between two organic manure producing process, you also need the belt conveyor to deliver the materials. The detailed information about these two machines are as follows.

The above content is for your reference only. There are various types of the fertilizer production equipment in SX. You can run the $45,000 organic fertiliser production line according to your actual demands. If you have the special requirements, we will try our best to meet them as long as it is reasonable.

How To Buy The Organic Fertilizer Machines Within The Budget Of 450,000 Usd$?

The SX production equipment of organic manure has different specifications. Then how do you buy production equipment within $45,000 to set up an organic manure production line with relatively high capacity? Our company has a complete feedback professional team and design team. If you choose us, we will help you complete the overall fertilizer production project planning for you. Of course, we will also help you buy relatively good production equipment within the budget. You can purchase the organic fertilizer production equipment by considering the following aspects.

The above suggestions are for reference only. You can select the machines according to your actual organic manure production demands and your budgets. Also, you can ask us for the further detail information about the organic fertilizer production equipment.

How Do I Select The Production Site For The $45,000 Organic Fertilizer Production Plant?

As a new starter of building the organic fertiliser production line, you need to consider a problem besides the selection of the organic materials and the production equipment. The problem is to sit and area of the organic manure production plant. Generally, the area of the $45,000 organic fertiliser plant is 1500 m2. Then how do you choose the right place for the $45,000 organic fertiliser plant? We advise you can consider this problem from the following aspects.

The Distance To Organic Fertilizer Supplier

The farm is the main raw material origin. Because of the big volume and high water content of the animals manure, it is not convenient for you to transport them. Therefore, you’d better make the organic fertilizer plant closer to the farm. By doing so, you can cut down the transport cost. However, you should not set up the fertilizer plant too close to the farm in order to save transportation costs. Or it is easy to infect diseases, which brings difficulties to the epidemic prevention of breeding plants. Generally, organic fertilizer plants should not exceed 50 km from where raw materials are supplied.

The Distance To The Residential Area

The organic fertilizer plant should far away from the place where people live. Because there will be odious gas produced during the fertilizer production. Thus, the distance to the residential area should not less than 500m. In addition, the living and working area in the factory should also be set in the upper place of the organic fertilizer production area.

In addition to the above two points, you should also ensure that there is no problem for the water and power supply of the organic manure plant. The site selection of organic fertiliser plant is very important .You need to consider what the impact it will have on the surroundings during organic manure production and fermentation. You should choose the organic fertiliser production site for environmental protection. When choosing the site , you can consult with relevant experts. Or you can contact with us, we will provide you with a professional team to help you complete the planning of the organic fertiliser site and the assembly of the organic manure production line.

The above is about how to start the $45,000 organic fertilizer production business. They are summarized through the years of our experience. The suggestions can be your references. When managing the organic manure production line, you can communicate with us for the detailed information.