Why Do So Many People Set Up The Urea Based Compound Fertilizer Production Line?

The urea-based compound fertilizer produced with fertilizer has the advantages of high utilization rate and high economic benefit. It is precisely because of these two advantages that more and more fertilizer manufacturers have begun to produce urea-based compound fertilizers. You can learn more detailed information about the advantages from the followings.

In the fertilizer sales market all over the world, the urea fertilizer has a lower price. Therefore, when using the urea as the based fertilizer of the compound fertilizer, you will get 25% higher economic benefit than before.

In terms of the fertilizer utilization rate, when using the urea fertilizer alone, there will be some problems like like volatile and hydrolyze easily problems due to high solubility. These problem can reduce the urea utilization rate to 30%-40%. However, practical experiments have proved that when blending a variety of nutrients evenly in proportion by the fertilizer mixing machine, you will produce high-quality urea-based compound fertilizer. By being applied such compound fertilizer, the yield of crops is about 15% higher than that of using single nutrient fertilizer. Therefore, the urea based compound fertilizer has improved the fertilizer utilization rate.

From the mentioned above, you can make more benefits from producing the urea based compound fertilizer. while making the urea-based compound fertilizer. The followings will do a great help for you.

What Technology Can You Apply To While Setting Up The Urea Based Compound Fertilizer Production Line?

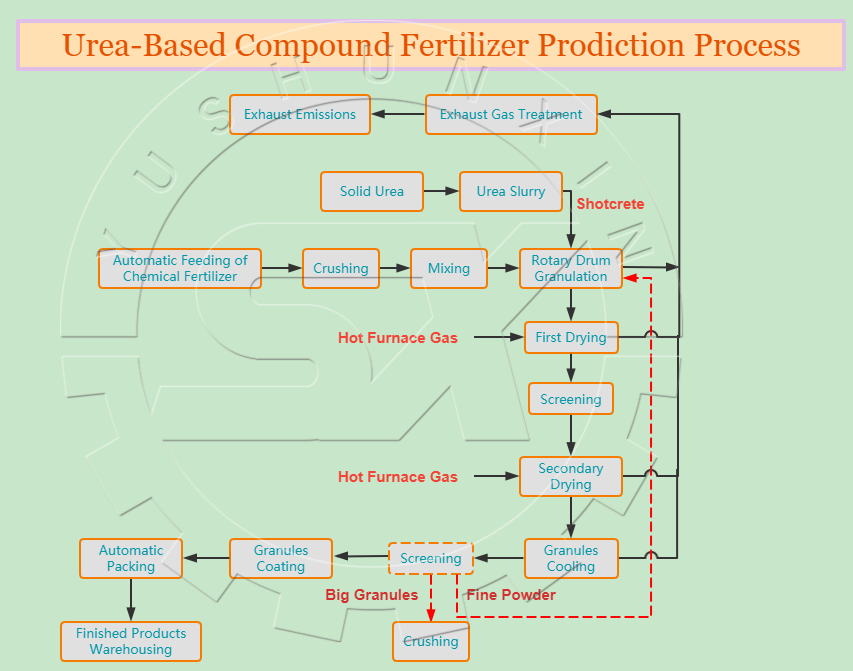

There are two methods you can apply to produce the urea-based compound fertilizer. One is the agglomerate granulation, and the other is blending method. The specific description are as follows.

The Agglomeration And Granulation

Before granulation, you should crush urea, ammonium phosphate, potassium chloride and others by the crushing machine at first. Then, you can feed them into the granulation machine. With the help of steam or liquid, raw materials will gradually form granules under the mechanical action of the granulator. In order to ensure the strength of fertilizer particles, you can add some granulation additives, such as formaldehyde, gypsum, etc. to improve the physical properties of the product. When there are magnesium elements in your fertilizer formula, you should supplement magnesium hydroxide. You can also add the nitrification inhibitors, pesticides and herbicides into the raw materials.

The Blending Method

When you use the blending method to make urea-based compound fertilizer, you only need to evenly mix the basic fertilizer urea with other raw materials with similar particle size such as ammonium phosphate and potassium chloride. In this way, you can sell the compound fertilizer in bulk or in packaging.

Through comparing these two-production methods of the urea-based compound fertilizer, you can know that the blending method is simpler than the agglomeration and granulation. And when applying the blending method to make the urea based compound fertilizer, you can invest less than that of applying the agglomeration and granulation. However, the fertilizer particles produced by agglomeration and granulation will be not easy to stratified and more stable. Therefore, we recommend you choose the agglomeration method to make the urea based compound fertilizer. You can also provide us with your production yield and budget. We will recommend the suitable urea based compound fertilizer production line for you.

What Machines Will You Use Before Granulating The Urea Based Compound Fertilizer?

While applying the agglomeration granulation, there are four steps you should do at this stage. Moreover, you should buy the machines for steps of the crushing, screening,batching and mixing. The machine used in each step are as follows.

Step1: Crushing Machine

While applying the agglomeration method, you should use the powder fertilizer as the raw materials. Therefore, you should use the fertilizer crushing machine to crush the urea, potassium chloride, ammonium phosphate and other materials to the powder with the diameter of less than 2.8mm. When you need to crush the raw materials, there are many types of the crushing machines in FPC you can choose. We designed the urea crusher specially. While using the urea crushing machine, you can get the urea granules with the diameter of 0.3mm-0.5mm.

Step2: Screening Machine

After crushing, there must be some unqualified powders in the materials. You should use the screening machine to remove the substances. While screening, we recommend that you use the rotary screening machine produced by FPC. You can sieve the 1-20 tons of the fertilizer per hour by using the FPC rotary screening machine.

Step3: Automatic Batching System

When producing the high-nutrients urea-based compound fertilizer, you should accurately measure the amount of each raw material according to the production formula. In order to prorate the base fertilizer precisely, the automatic batching system is more suitable for you. There is the dynamic batching system in FPC. By using the FPC dynamic automatic batching system, you can batch the raw materials continuously. By this way, you can improve the urea based compound fertilizer production efficiency.

Step4: Mixing Machine

After the batching process, you should mix the raw materials completely to ensure the even distribution of nutrients. For the fertilizer mixing process, FPC design many types of the mixer with the capacity of 1-20t/h. You can select the mixing machine based on your budget and urea based compound fertilizer production line yield.

The above four machines are that you need to use before granulation. There are different technical parameters of the production machines in FPC. Once choosing FPC, you will get multiple choice of the urea based compound fertilizer production equipment.

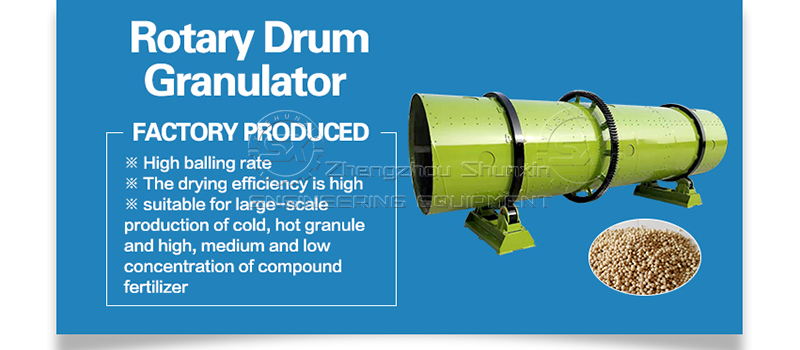

What Granulation Machine Can You Use For The Urea Based Compound Fertilizer Production Line?

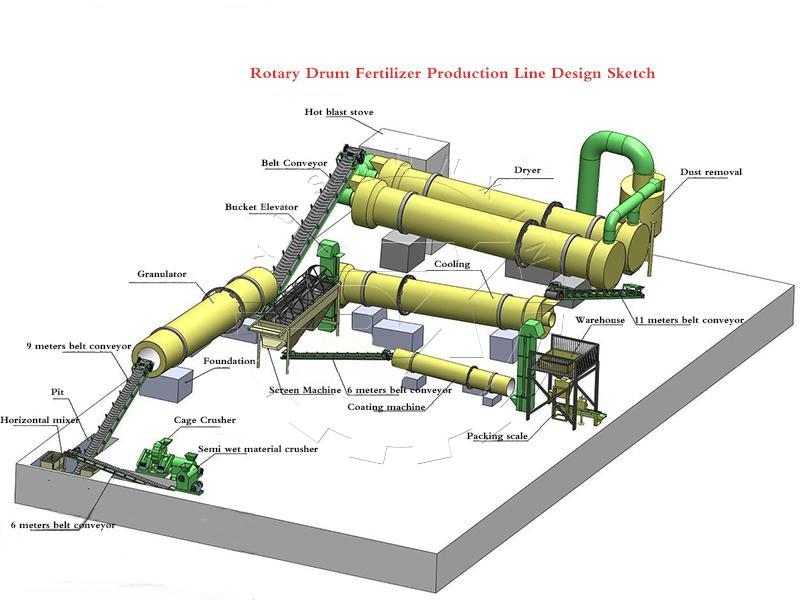

While granulating the urea based compound fertilizer, we recommend you use the rotary drum granulation machine. For getting higher granulating efficiency, FPC has improved the rotary drum granulating machine. You can know more about the technical parameters of FPC rotary drum granulator from the following.

Because of the above advantages of FPC rotary drum granulator, many fertilizer makes would like to deploy it. When granulating, the rotary drum fertilizer pellets making machine might be your best choice.

What Other Machines Do You Need After Granulation For Setting Up The Urea Based Compound Fertilizer Production Line?

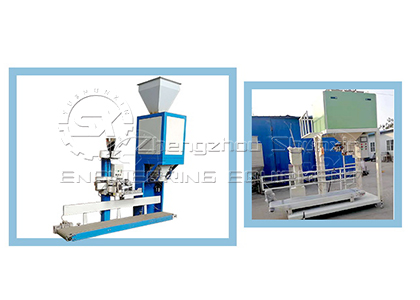

To get the quality urea based compound fertilizer, you should still process the granulated fertilizer. There are still four processes you should know after granulation. You also need to deploy the machines for drying, coating, screening and packing. The detail descriptions are as follows.

After the granulating process, you will get the urea based compound fertilizer granules with the temperature of 60 ℃ and the moisture of 2.5%. In order to improve the strength of the fertilizer granules, you need to use the rotary drying machine to reduce the extra moisture.

Because the nitrogen element of compound fertilizer will start to hydrolyze at 60 degrees, and too high temperature will accelerate the formation of biuret which is harmful for the crops. The above two problems will lead to the destruction of nutrients in compound fertilizers. Therefore, you should control the drying temperature at the range of 60℃-70℃.

Because raw materials such as urea will undergo a hydrolysis reaction under conditions that contain a certain amount of moisture. And this reaction still occurs during storage. Such a reaction can cause the product to agglomerate. In order to avoid this situation, you need to reduce the moisture of the urea based compound fertilizer pellets to less than 2%.

As mentioned above, you also need to buy other four machines to set up the urea based compound fertilizer production line. When purchasing these machines, you can contact with us. We will give you some reasonable suggestions about the machine’s selection.

What Is the Price of the Whole Urea Based Compound Fertilizer Production Line?

The price of urea based compound fertilizer production line is related to its configuration and yield. In the market, there are different scales of urea based fertilizer processing lines for sale. All of them are on sale at the different prices. When buying one set of urea based compound fertilizer processing line at the best price, you should figure out the following.

There are many scales of urea based compound fertilizer production lines for sale in FPC company. You can get entire set of fertilizer processing line at best cost. You can email us for more details about this urea based compound fertilizer making line. We will recommend the most suitable production line for your fertilizer manufacturing plant.

Where Can I Buy a Complete Set of Urea Based Compound Fertilizer Making Line?

From the above, you know that many types of urea based compound fertilizer making lines are on sale in FPC company. We have many years of experience in design, production and installation of fertilizer production lines. You can get the ideal urea based compound fertilizer production machines and line from us. What’s more, there are many services you can enjoy when choosing FPC company, such as multi choices, customization and technical support. You can know the details from the following.

We have more than 15 years of fertilizer equipment production industry experience. You can trust our working and producing ability. We have the confidence to supply quality urea based compound fertilizer production line to you. Get free inquiry now, you can enjoy big promotion.

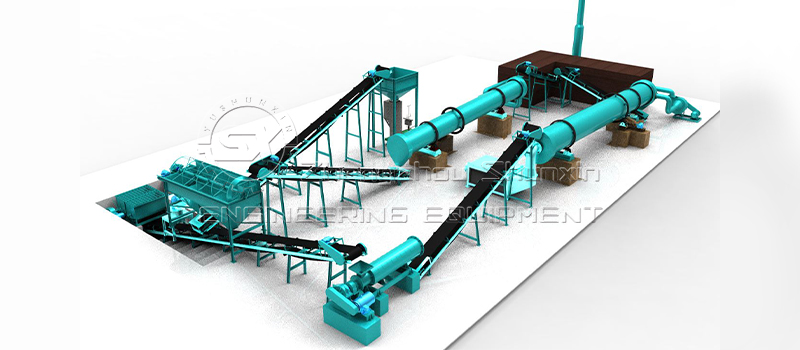

How Do We Design The 20t/h Urea Based Compound Fertilizer Production Line For The Customer From Apapa Lagos,Nigeria?

We once designed a granulation line for urea-based compound fertilizer for a customer from Nigeria. You can know more detailed information of this deal from the following.

The Nigeria customer want to make urea-based compound fertilizer from the use the urea, ammonium nitrate, phosphorus and potassium. According to the raw materials, we propose the specific urea based blending fertilizer production process to the customers. You can also provide us with the raw materials. We will design the suitable production plan for you.

The customer from Nigeria intend to produce 20 tons urea based compound fertilizer per hour. Then we provide him with the probable investment cost while setting up the 20t/h compound fertilizer production line. Generally, we will calculate the production line budget from the equipment price, transportation charge and other aspects.

We send the latest quotation of production equipment to the Nigeria customer. After that, we discuss the quality and performance of machines. Because of the large transaction volume, we give the customer a certain discount. We have the regular promotions. You will get the compound fertilizer equipment at the best price during this promotion period.

We have the customized service, on-site installation service and other special services. From the pre-sale to the installation of the machines, we also provided the Nigeria customer with long-term warranty. Therefore, you will get the complete guidance from us.

We guaranteed the customer to complete the production within just 1 month working days. Then we arranged the best capable transport company to deliver the goods. Under the normal condition, we will finish equipment production within only 30-40 working days. Therefore, your production plan will not be delayed.

Through the above, you can know how we designed the urea based compound fertilizer granular production line for this Nigerian customer. FPC is a company engaged in the compound fertilizer equipment production for many years. You can completely believe that we have the ability to provide you with high-yield and high-quality compound fertilizer production lines.

Many customers highly praise the quality of FPC urea based compound fertilizer production line and equipment. Therefore, you could trust that we can provide you with qualified production lines and machines. We will also give you more special service like customized service, on-site installation, machine test video. If you intend to produce the urea-based compound fertilizer, please contact with us.