Bir NPK gübre tesisi en iyi maliyetle nasıl çalıştırılır?

Bir NPK Bileşik Gübre Üretim Projesi planlarken, Ne düşünmelisin? En önemli kısım maliyettir. Öyleyse, NPK gübre tesisi maliyetini hesapladığınızda, Hangi yönleri düşünmelisiniz? Yıllarca süren deneyimimize göre, var 6 Dikkate almanız gereken noktalar. Altı yön aşağıdaki gibidir.

NPK Bileşik Gübre Fabrikasının maliyetini hesaplarken altı yön referansınız olabilir. Bize NPK Bileşik Gübre Üretim Planınız hakkında da bilgi verebilirsiniz.. Gübre Üretim Şirketi oluşturmak için size en iyi planı vereceğiz.

Bir NPK Tozu Gübre Tesisi kurarken ne kadara mal olacak?

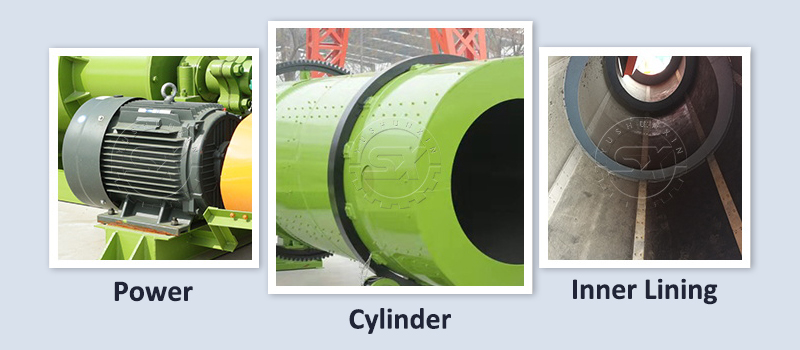

Gübre bitkisini inşa ederken, Makine dağıtılabilir. Toz NPK gübresini üretirken, Makineleri parti için satın almanız gerekiyor, ezici, Karıştırma, tarama ve paketleme. Takipler bu beş makine hakkında.

Toplu sistem

Kapsamlı besinlerle toz NPK gübre yapmak için, Formül oranını kesinlikle takip etsen iyi olur. Öyleyse, Bileşik gübre toplu makinelerini parti işleminde kullanabilirsiniz.. FPC Dinamik ve Statik Otomatik Toplu Makineler, malzemeleri daha doğru ve verimli bir şekilde tamamlayabilir. Dahası, FPC'de gübre toplu ekipmanının birçok tür ve spesifikasyonu vardır..

Kırma makinesi

Düz gübrenin farklı boyutları var. Besinlerin eşit olarak dağıtılmasını sağlamak için, Hammaddeleri tek tip boyutta ezmeniz daha iyi olur. Dahası ne var, Ezilmiş NPK gübresi mekanik gübrelemeye elverişlidir. Gübre malzemelerini ezmek için daha etkili, Kullanmanızı tavsiye ediyoruz FPC Yeni Tip Dikey Ezme Makinesi. NPK Gübre Üretim Bütçenize göre kırma makinesini seçebilirsiniz..

Karıştırma ekipmanı

Besin dağılımını eşit olarak yapmak için, kullanabilirsiniz Gübre karıştırma makinesi. Çünkü FPC karıştırma makinesi düşük enerji tüketimi ve yüksek çalışma verimliliği özelliklerine sahiptir. Örneğin, SXSJ-0830 Yatay mikser tüketimi 11 KW. Karıştırma hızı dakikada 35R'ye kadar olabilir. Böylece, Enerji tüketimini düşürebilir ve karıştırma verimliliğini artırabilirsiniz.

Tarama makinesi

Kullanarak tarama makinesi, NPK gübre saflığını artırmak için niteliksiz maddeleri çıkarabilirsiniz. FPC'nin ürettiği döner tarama makinesi, katı malzemeleri 300 mm'ye kadar boyutta elemeyebilir.

Ambalaj makinesi

Üretim verimliliğini artırmak için, kullanabilirsiniz otomatik paketleme makinesi paketleme hızını hızlandırmak için. FPC otomatik paketleme ölçekleri saatte yaklaşık 250-300bag gübre paketleyebilir. Dahası, Hataları otomatik olarak düzeltebilir.

Yukarıdakiler, NPK tozu gübresi için dağıtmanız gereken gübre üretim ekipmanıdır.. Farklı Gübre Ekipmanı Üreticilerinden Makineler Fiyatını Karşılaştırarak Toz NPK Yapma Ekipmanı maliyetini hesaplayabilirsiniz..

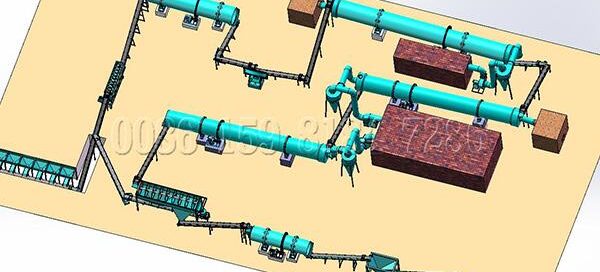

Granüler NPK Gübre Üretim Hattı En İyi Maliyetle Nasıl Özelleştirilir?

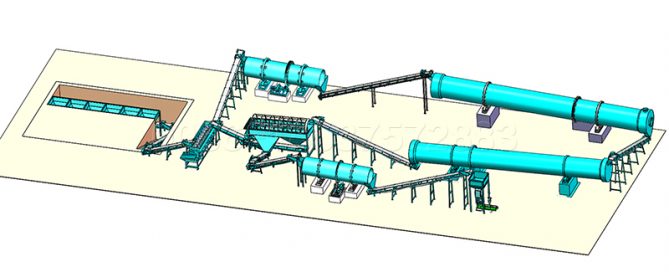

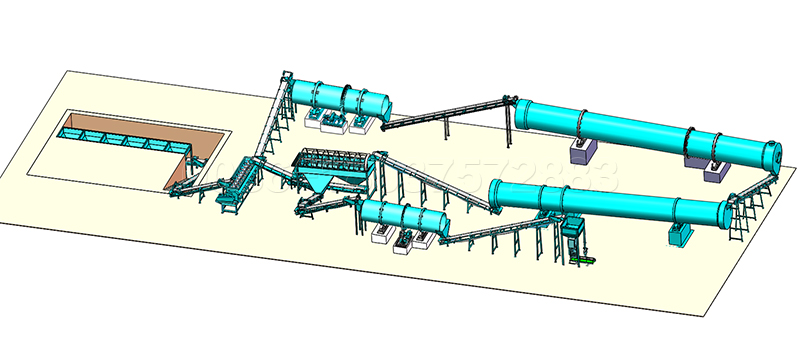

NPK tozu gübre bitkisi ile karşılaştırıldığında, Granüler NPK Gübre Tesisi için daha fazla gübre makinesi dağıtmanız gerekiyor. Öyleyse, Granüler NPK gübre fabrikasının maliyeti, toz olandan daha fazladır. Takipler, NPK Granülleri Üretim Hattı için dağıtmanız gereken makinelerdir.

Yukarıda belirtildiği gibi, NPK Gübre Tesisi Maliyetinize göre üretim tesislerini satın almanız gerekir.. NPK Granüler Gübre tesisinin bütçesi sınırlıysa, Kurutucuyu ve soğutucuyu insan gücü ile değiştirebilirsiniz. Fakat, Bu makineleri dağıttıktan sonra granüler NPK gübre üretim hattının yüksek üretim verimliliğini elde edebilirsiniz..

Ne’S NPK Gübre Tesisi Proje Maliyeti?

NPK Gübre Tesisi İşine Başlarken, Üç açıdan tüm maliyeti göz önünde bulundursanız iyi olur. Dikkate almanız gereken bazı yönler var. Ayrıntılı bilgileri aşağıdakilerden alabilirsiniz.

İdeal gübre ekipmanı üreticilerini nasıl seçerim?

NPK gübre tesisinin yatırım maliyetini düzenlemek için, Seçmelisin gübre ekipman üreticileri kesin olarak. Seçerken, Bunu üç açıdan düşünmenizi öneririz. Ayrıntılar aşağıdaki gibidir.

Yukarıdaki üç yönü göz önünde bulundurarak, İdeal NPK Gübre Ekipman Tedarikçileri'ni seçebilirsiniz. Dahası ne var, NPK gübre üretim hattını en iyi maliyetle kuracaksınız.

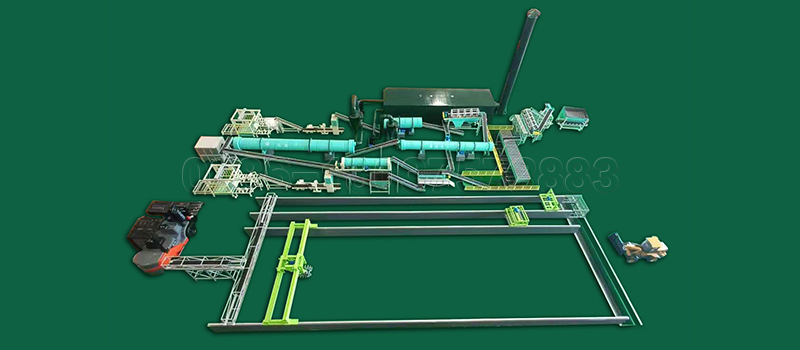

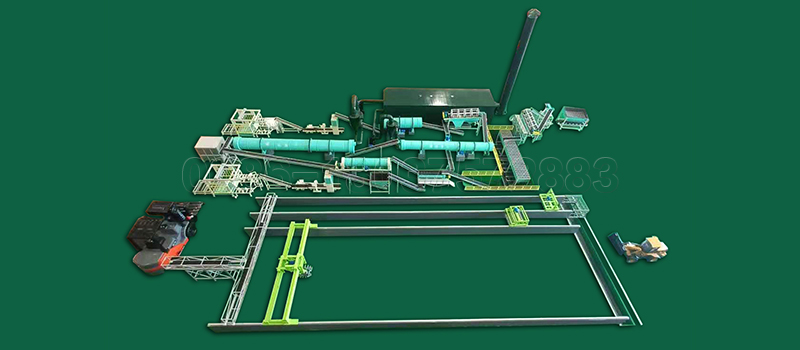

NPK gübre tesisi en iyi maliyetle nasıl tasarlanır?

Planlama yatırımından tasarruf etmek için, İnşaat süresini kısaltın, Üretim maliyetini azaltın, ve arazi kaynaklarını tam olarak kullanın, Üretim ihtiyaçlarına göre fabrikayı aşağıdaki üç bölüme bölebilir ve kullanım işlevi

Fabrika fonksiyon bölgesinin bu kadar açık bir bölünmesi yoluyla, Sadece bitki alanını rasyonel olarak düzenleyemezsiniz, aynı zamanda insanların akışını ve lojistiğini daha uygun hale getirin. Öyleyse, NPK gübre üretim tesisinin çalışma verimliliğini artırabilirsiniz.

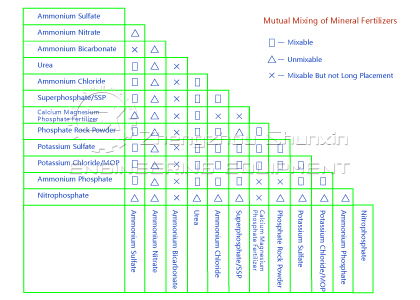

NPK gübresini yapmak için hammaddeleri nasıl toplarım?

NPK bileşik gübre hammaddelerini toplarken, Temel gübrelerin kimyasal özellikleri hakkında net olmanız daha iyi olmanızı öneririz.. Böylece, Kaliteli NPK gübresini üretebilirsiniz. İşte sizin için üç ipucu.

Yukarıdaki üç yöne dikkat ederek, Malzeme atıklarını azaltabilirsiniz. Dahası ne var, Kaliteli NPK bileşik gübresini nitelikli hammaddelerle üreteceksiniz.

Farklı üretim ölçeklerine sahip NPK gübre bitkisinin maliyeti

NPK gübre tesisinin farklı üretim ölçekleri farklı bütçeye sahip olacak. Yıllarca süren deneyimimize göre, Üretim ölçeğini üç aralık 1-5t/s'ye bölebiliriz., 5-10T/H ve 10-20T/H. Aşağıdaki içerik referanslarınız olabilir.

1-5t/s üretim ölçekleri

NPK gübre tesisini bu tür üretim ölçekleriyle inşa etmek için nispeten düşük bir yatırım maliyetiniz olacak. Örneğin, üretirken 5 Ton NPK Gübre Peletleri Saatte, Sadece SXYZ-3600 PAN Granülatörü satın almanız gerekiyor.

5-10t/s üretim ölçekleri

Yaparken 5-10 Saat başına NPK gübresi tonlarca, Gübre bitkisini orta ölçekli inşa etmelisiniz. Böylece, Daha yüksek bir NPK gübre tesisi maliyeti almalısınız. Örneğin, Hakkında hazırlamalısın $100,000 10T/H NPK Gübre Üretim Hattını Kurmak İçin.

10-20t/s üretim ölçekleri

Bu büyük bir NPK Gübre Üretim Fabrikası. Böyle bir NPK gübre işini başlatırken, Başkentini fazla hazırlamalısın $150,000. Ancak bu tür gübre üretim tesisini yürütmekten daha fazla kar elde edeceksiniz.

Yukarıdakiler aracılığıyla, Farklı ölçekler için NPK bileşik gübresinin bitki maliyetini hesaplama hakkında daha fazla bilgi edineceksiniz. Dahası ne var, NPK gübre tesisini inşa ederken bizimle iletişime geçebilirsiniz.. NPK Gübre Üretim Hattı Seti hakkında size en son kota sağlayabiliriz.

Farklı bütçelerle NPK gübre tesisi nasıl kurulur?

Farklı bütçelerle, NPK gübre tesisini farklı ölçeklerle kurabilirsiniz. Deneyimlerimizden özetlendiği gibi, Bahsetebileceğiniz üç bütçe aralığı vardır. İlk bütçe aralığı $10,000-$30,000, ikincisi $30,000-$50,000, Üçüncüsü bitti $50,000.

Yukarıdaki veriler sadece referansınız içindir. Gübre makinelerini ve üretim hattını gerçek üretim durumunuza göre değiştirebilirsiniz.. FPC'yi seçerseniz, Size bazı makul öneriler sunacağız.

Eski marka bileşik gübre ekipmanı tedarikçisi olarak, Gübre makinelerimizi yurtdışına ve yurtdışına sattık. Dahası, Müşterilerimiz, FPC tarafından üretilen gübre yapma makinelerinin kalitesini büyük ölçüde övüyor. Öyleyse, NPK gübre fabrikasını inşa ederken, Bize e -posta gönderebilirsiniz. Gübre üretim ekipmanını en iyi fiyata alacaksınız. NPK gübre tesisini de en iyi maliyetle inşa edeceksiniz.