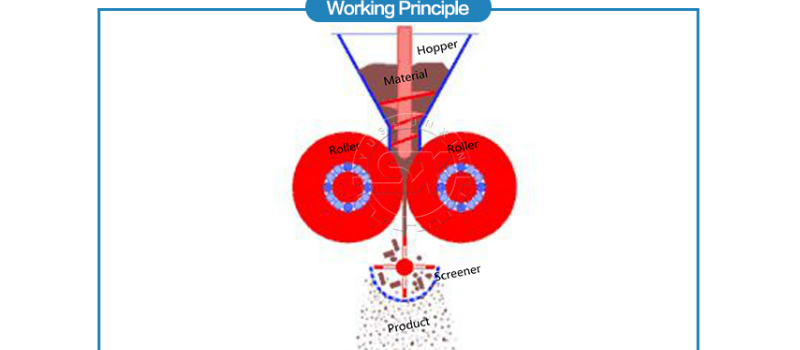

The double roller extrusion granulator is an excellent fertilizer pellets making equipment. The double-roller press fertilizer pellets making machine adopts the dry granulation. For granulating the powder fertilizer, more and more fertilizer makers choose to use the double-roller pellet machine. It is because that there are many advantages of the double roller extrusion granulating machine. SX designs many kinds of the double roller press granulation machine. While granulating, many fertilizer manufacturers would like to use the SX double-roller extrusion machine. You can know about the reason by reading the following. As the fertilizer equipment producer with years’ experience, we can also offer some skills about operating and maintaining the double roller extrusion granulating machine. Ovviamente, we can also give you technical support if you need.

When producing the granular organic fertilizer, there are many people to choose the SX organic fertilizer double roller extrusion granulation machine for the granulating process. What are the advantages of the SX double roller pellet press pelleting machine? You can know the answer from the following.

Come accennato in precedenza, you can know about the advantages about the double-roller extrusion pelleting machine produced by SX. Because of these advantages, more and more fertilizer makers choose the SX double-roller press granulating machine.

What Is The Detailed Technical Parameters Of The Sx Double Rollers Extrusion Granulator?

There are many types and specifications of the double roller pellet machine produced by SX. We can guarantee that the granulation machine you buy must be high quality and working efficiency. You can know about the specific technical parameters from the followings.

In addition to the above technical parameters, we also choose the excellent materials to produce the double roll extrusion grain making machine. Per esempio, our frame material is carbon steel plate. Perciò, you can believe in the quality of our granulation machines.

| Model | Powder(KW) | Granule Diameter(mm) | Roller Sheet Size (mesh) | Dimension(mm) |

|---|---|---|---|---|

| SXDJ-1T | 15 | 4-10 | 150×220 | 4100×1600×1150 |

| SXDJ-1.5T | 18.5 | 3-10 | 150×300 | 4250×1850×1300 |

| SXDJ-2T | 22 | 3-10 | 185×300 | 4700×2350×1600 |

How To Operate The Double Roller Extrusion Granulator?

In order to get the high working efficiency of the double roller press granulating machine, you should know that how to operate the machine safely. You can refer to the following.

Before Granulating

Before starting to granulate the powder fertilizer, you need to preheat the double-roller press granulating machine for about 50 minutes. Because in the normal granulation process, it needs to continue to add heat. Oltretutto, you have to adjust the temperature appropriately according to different materials.

While Granulating

When operating, the temperature of the granulation machine needs to be stable. The temperature of the granulator head part should be kept at about 200℃. When feeding the fertilizer materials, you should note to convey the materials evenly. Otherwise, the pellet quality and yield of the fertilizer will be affected.

After Granulating

After the granulation process is completed, you should make sure that the power supply of the machine is completely disconnected. Inoltre, you must take off the plug of the machine head. In questo modo, you can make sure the granulation machine has stopped working completely to keep working situation safe.

By operating the double-roller extrusion granulating machine in this way, you can get a granulation machine with high processing capacity. Inoltre, you can improve the fertilizer pellets production efficiency.

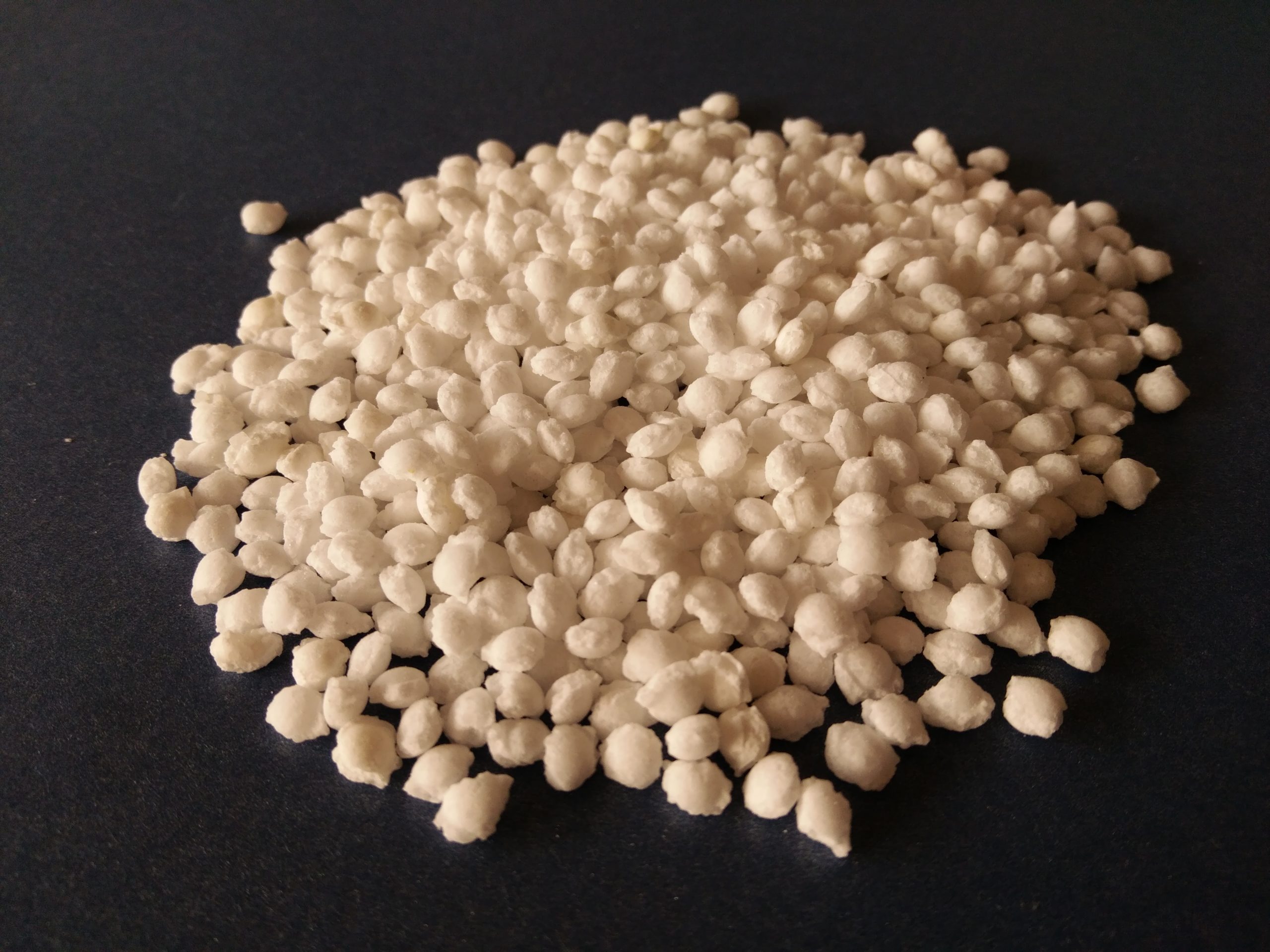

How To Adjust The Double Roller Extrusion Granulator To Control The Particles Sizes?

Dopo granulando, you may find that the fertilizer particles doesn’t meet your production requirement. Then how to change the particles size by adjust the double-roller pellet machine? You can adjust the following two parts to change the granules size.

Following the above two aspect, you can operate the double roller type fertilizer pellets making machine more effectively. Per di più, you can get the qualified fertilizer granules by adjusting the granulation machine.

How To Avoid Abrasion Of The Roller Skin On The Double Roller Extrusion Granulator?

In fertilizer production, there must be some damages on the roller skin of the double-roller pellet press granulation machine. If you apply the granulating machine more properly, you can reduce the damage of the roller skin and prolong the using time of the granulation machine. But what is the preventive measure of avoiding the roller skin wear? The followings you can refer to are the preventive measures.

The Fertilizer Materie prime

There are some impurity substances like steel and stones which will damage the roller skin. Perciò, before granulation, you should remove the slag and useless raw materials through using la macchina per lo screening del fertilizzante. When granulating the raw materials with high moisture and pH, you should inspect the roller skin regularly.

The Fertilizer Feeding Speed

Because the roller skin will be damage due to the uneven force produced by the inconstant speed of feeding materials. Perciò, when you granulate the powder fertilizer with the double-roller press granulation machine, you should feed the powder fertilizer into the machine with the constant speed. In questo modo, there will be less granulation machine abrasion while using it.

While operating the double-roller extrusion granulation machine through noting the above two aspects, you can cut down the maintenance cost. Perciò, the proper use and maintenance are the key way to reduce wear of the roller skin.

How to Maintain the Double Roller Extrusion Granulator?

In order to cut the cost of purchasing granulation machine, you should maintain the machine regularly and prolong the service life. But how should you do? You can refer to the following suggestions.

The prerequisite for extending the service life is to maintain the machine correctly. Perciò, in order to granulating normally, you need to observe the working status of the double roller extrusion granulation machine so that you can solve the problems in time. You can contact with us to solve the problems about the double-roller pellet machine. Out technical staff can give you technical support.

Attraverso quanto sopra, you will get a further understand about the double roller press granulation machine. In SX, there are many specifications of the machine you can choose. In addition to provide you high-quality fertilizer production machine, we can also give you professional technical support. If you need the granulation machine, you can contact with us anytime.