Cómo diseñar la línea de producción de fertilizantes orgánicos con 35,000 Dólar estadounidense $?

Mientras comienza una planta de fertilizantes orgánicos, how do you design the organic fertilizer production line with $35,000? There are four factors you need to consider. They are fertilizer type, production process, organic raw materials and equipment selection. You can know more about them from the following.

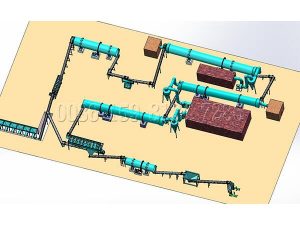

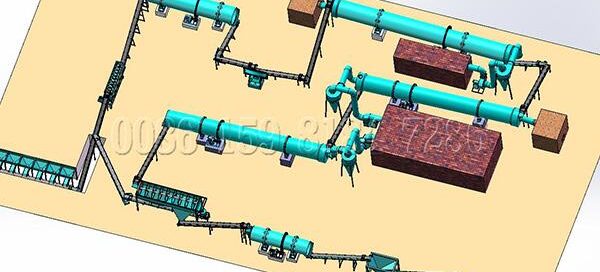

SX is a company specializing in the production of organic fertilizer production equipment for a long time. We have special organic fertilizer production line design team and equipment production personnel. We constantly improve the organic fertilizer production equipment. De este modo, we can provide customers with simple structure, high efficiency and easy maintenance of production machinery. You can also experience the customized service. For the organic fertilizer production line, we can provide you with the design in detail according to the site drawings, budget amount and output you provide. We will show you the organic fertilizer production line model and the capacity of related machinery in advance. We also provide you with the latest quotation about organic fertilizer production equipment.

How To Design The Organic Fertilizer Production Line With 35,000 USD dollar?

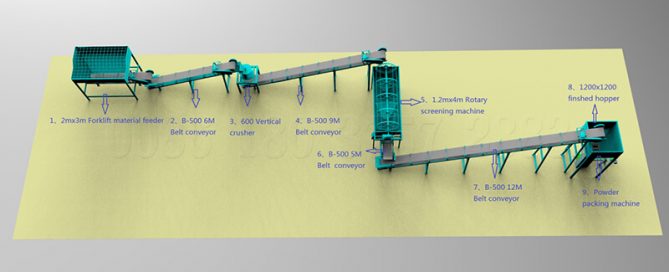

When you want to run the organic fertilizer manufacturing business and your budget is $35000, we recommend you assemble the powder organic fertilizer production line. It is a very simple organic fertilizer production line. There are only four steps in the technological process of the powder organic production line. They are composting, crushing, screening, packaging.

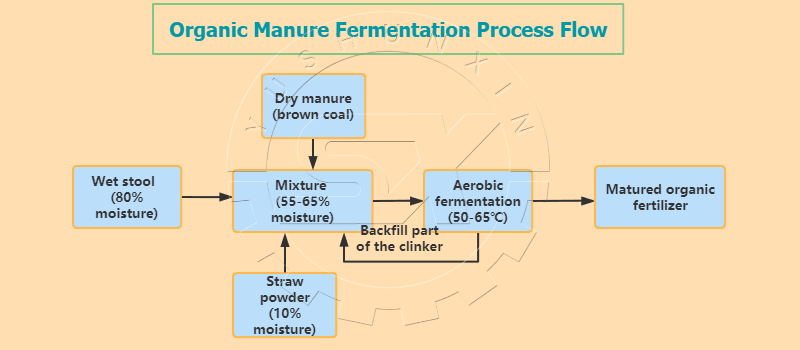

You will ferment the organic materials very well through noting the above four aspects. En el proceso de compostaje, you can use the organic fertilizer compost turner machine. By flipping, the machine can regulate the moisture temperature ans ventilation. ¿Qué es mas?, it has the action of mixing and crushing materials.

Crushing Process

After composting,there will be some bulk organic manure in the material piles. You need to crush the bulk organic manure to meet the powder organic fertilizer packing requirements. Then how do you crush the organic manure? After composting, you should add the organic waste with 30% – 35% water content into the fertilizer loader type feeder by using the tractor shovel. Then the organic waste transported by the belt conveyor will be delivered evenly to the fertilizer crusher. Through the crushing, the organic fertilizer will have a beautiful appearance. Además, you can get the quality powder organic fertilizer.

Screening Process

In order to meet the requirements of powder organic fertilizer fineness in production, you need to grade the crushed organic fertilizer. puedes usar la máquina de cribado de fertilizantes to screen out these organic fertilizers that do not meet the requirements. Al hacerlo, not only it is more convenient for the final step packing process, but also you can ensure the quality of the finished organic fertilizer.

Packaging Process

You need package the organic fertilizer after screening according to the specified weight. In order to make organic fertilizer packing process more efficient, you can use the automatic packing scale machine. Using automatic packaging machine, you can not only reduce the manpower investment, but also more accurately package organic fertilizer.

From above mentioned, you can know that the powder organic fertilizer process is simple. But during the organic waste compost process, you need consider many factors. After all, the composting process is the most important step in the organic fertilizer production process. It will the quality of the finished organic fertilizer. Then you can complete the other three steps by using the organic fertilizer production machines. Sin embargo, which type of the organic production equipment should you choose? The following will give you some advice.

When Composting,What Machine Can You Use For The $35,000 Línea de producción de fertilizantes orgánicos?

From above mentioned, you can know that the powder organic fertilizer process is simple. But during the organic waste compost process, you need consider many factors. After all, the composting process is the most important step in the organic fertilizer production process. It will the quality of the finished organic fertilizer. Then you can complete the other three steps by using the organic fertilizer production machines. Sin embargo, which type of the organic production equipment should you choose? The following will give you some advice.

How To Deliver The Organic Fertilizer During The $35,000 Organic Fertilizer Production Line?

Many of our customers choose to use our fertilizer loader type feeder when sending the composted materials to crush. The SX loader type feeder produced by SX is widely used. It can be used not only in organic fertilizer production industry, but also in chemical industry, machinery and other industries. Why is SX fertilizer loader type feeder so popular with our customers? Because our forklift feeding machine has great structural advantages. What are these structural advantages?

The capacity of our forklift feeder silo is 5m ³. So you can greatly reduce the working intensity of forklift operators by using forklift feeder with large capacity bin. Al mismo tiempo, the staff can also operate the composting turner machine for turning organic manure work. When using forklift feeding machine, you can realize the automation of organic fertilizer production line and improve the production efficiency of organic fertilizer.

In order to improve the utilization rate of fermentation organic manure, our forklift feeding body adopts double arc design. Through this design, you can reduce the waste of materials produced in organic fertilizer production line.

The design purpose of strong traction is to improve the capacity of feeder to bear impact load. De esta manera, you will get the long-term service life of the fertilizer feeding machine.

The Most Suitable Fertilizer Crusher For The $35,000 Línea de producción de fertilizantes orgánicos.

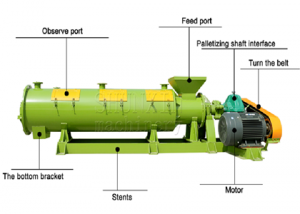

As above mentioned, after the composting, you will find some bulk organic manure in the composted materials. Por lo tanto, you need use the organic fertilizer crushing machine to make the organic fertilizer production line more efficient.There are six types of organic fertilizer crushing machine in SX. According to your budget of $35,000, the new type vertical crusher será tu mejor opción. For making the organic fertilizer mill work more efficient, we make some improvements in the original structure of the new type vertical crushing machine.

The three aspects are the structural advantages of SX vertical crushing machine. Además, the new type fertilizer vertical crusher made by SX also has the advantage of high working efficiency. Por lo tanto, the vertical shredding machine is more suitable for the $35,000 línea de producción de fertilizantes orgánicos.

The Ideal Máquina de detección For The Organic Fertilizer Production

Why do you use the screening machine in the organic fertilizer production line? De lo anterior, you know screen out the qualified organic manure when producing the organic fertilizer. De este modo, we suggest that you use the SX organic sieving machine when you need screen the materials. In order to improve the screening effect, SX improves the fertilizer rotary screening machine structure specially. After improving the structure, the organic fertilizer sieving machine has more advantages. The advantages you will see are as following.

Angle Of Inclination

When producing the organic fertilizer screening machine, we will set special inclination angle for the machine. The main purpose is to make discharge the organic manure more easily. Al mismo tiempo, you can improve the production efficiency of the organic fertilizer production line.

Various Feeding Methods

When you want to buy the organic fertilizer screening machine from SX, we can design the feeding inlet according to your actual organic fertilizer production site. Whether the belt, the funnel or other feeding methods, we can customize it. Además, there will be not any special device to set for you.

Vida útil a largo plazo

To prolong the service life, SX chooses the material of stainless steel for making the screening mesh. Al hacerlo, the sieving mesh has the characteristic of corrosion resistant. Whether or not there is a lot of impurities in the material to be sifted, the rotary screening machine can work normally.

High Screening Capacity

Compared with other types of the sieving machines in the same volume, there is a large effective screening area on the SX organic fertilizer screening machine. Por lo tanto, the amount of organic fertilizer screened in unit time is large. Your organic fertilizer production line will be more efficient.

A través de lo anterior, you will know about the SX fertilizer screening machines advantages. While purchasing the sieving machine, the SX screening equipment will be your better choice.

The Efficient Packing Machine For Designing $35,000 Línea de producción de fertilizantes orgánicos.

The last step of the powder organic fertilizer production process is packaging. What packaging machine can you buy for the organic fertilizer production line? Según tu presupuesto, the single bucket automatic packing scale is more suitable for you. There are two reasons for you to choose the SX organic fertilizer automatic packing machine.

SX single bucket automatic packaging scale is equipped with quality sensors imported from abroad. After many experiments, we control the precision of packaging at about 2‰. By equipping with higher accuracy metering device, you get the organic fertilizer automatic packing scale with high efficiency.

The SX single bucket automatic packing scale has multi purposes. When you add the organic manure into the bucket, the automatic packing machine will finish the bagging, unloading and sealing work automatically. By using the SX single bucket automatic, you can save a third of working time than manual packing.

Our organic fertilizer single bucket packing machine not only has a quick packaging speed, but also is easy to maintain. Por lo tanto, with SX organic fertilizer packing equipment, you will improve the packaging efficiency. También mejorarás la eficiencia de producción del abono orgánico..

What Else Auxiliary Machine Do You Need To Design Organic Fertilizer Production Line ?

To make your organic fertilizer production line more efficient, you need use the belt conveying machine to transport the organic manure when each production process finishes. By using the belt conveyor, you can avoid the directly contact with the organic manure to make sure the quality of the organic fertilizer. The belt conveying machine produced in SX has a high quality. In order make the conveying machine work normally for a lone time, we make some improvements on the structures of the conveyor. What are the improvements?

Como se muestra arriba, you can know how to design organic fertilizer production line with $35,000. Por supuesto, you can provide us with your budget or your organic fertilizer production area drawings. We will provide the suitable organic fertilizer production line for you. SX as the organic fertilizer production manufacturer with years of experience, we will try our best to satisfy your reasonable requirements.