In the fertilizer production industry, the flat die granulator is one of the most ideal pellets making machine. Besides granulating the based fertilizer, it can also connect with the pellet fertilizer polishing machine. Ved at gøre det, you can make the fertilizer granules at one time. Desuden, you can get the high-hardness fertilizer particles through using the flat die granulator. Derfor, more and more people will choose the flat die granulation machine to make the fertilizer pellets. To improve the working efficiency of the fat lie fertilizer pellets making machine, we make some improvements on the machine. By choosing SX, you can get the higher-efficiency and durable flat die pellet making machine. Desuden, as the fertilizer equipment producer with years of experience, we can provide you with reasonable suggestions on how to purchase and use the machine. Thus, you can choose the flat die granulator produced by SX without doubt.

How Can You Choose The Proper Flat Die Granulator Producers?

When you need to buy the flat die granulation machine, what you must consider is how to choose the high-quality and cost-effective machine. You can following three aspects for selecting the flat die pellet machine production plant.

After you understand these three principles, you will choose the capable fertilizer equipment producers. Desuden, you will purchase the flat die pellets making machine with high performance.

How To Choose Right Model Of The Flat Die Granulator?

In order to design the granule production line reasonably, it is very important to choose the right type of flat mould granulator. Which aspects can you consider to select the proper model of the flat die granulation machine? You can choose the flat mold granulator suitable for your production line from the following two aspects.

Produktionskapaciteten

There are different production capacities of the flat-die pellet machine with different specifications. When selecting the flat-die pellet fertilizer making machine, you should consider that how many fertilizer granules you intend to produce in an hour. For eksempel, when managing to make 2.5 tons of the fertilizer particles per hour, we recommend you choose the SXPM-600 flat die granulation machine.

The Budget

The flat die granulator price varies depending on its technical parameters. If you want to allocate the cost of granular fertilizer production reasonably, it is very necessary to choose the flat die pellet making machine suitable for the production line. For eksempel, for organic fertilizer pellet production line with the budget of $110,000, the SXPM-500 flat die pelletizer is the most suitable for your fertilizer production plant.

If you have no idea about the flat die granulation machine selection, you can ask our customers service staff for help. We will provide you some reasonable advice about the machine.

Why So Many Fertilizer Producer Use The Sx Flat Die Granulator?

For getting higher working efficiency of the flat die granulation machine, we have partially improved the structure of the machine. Derfor, you can not only use the flat die more effectively, but also use the granulation machine for a long time. You can learn more from the below.

It is precisely because of these benefits that so many people would like to use the flat-die fertilizer pellet making machine produced by SX. Derfor, you can get the high-efficiency flat die granulator from SX.

How Do We Design The Flat Die Granulator?

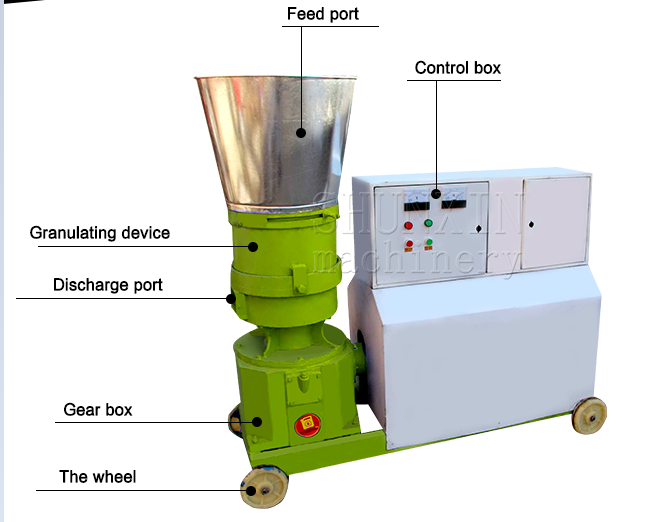

In order to improve the durability of the flat die granulator, we pay special attention to two aspects when producing the flat die pellet making machine. One is the rationality of the machine structure. The other is that the constituent materials must be strong and durable. You can learn how we produce and design the flat die granulation machine from the following four parts.

The Machine Frame

When you see the pictures of the flat die granulation machine, you can know about that all working parts of the machine are fixed on the frame. When producing the machine frame, we choose the medium-carbon steel plate and channel steel as the raw materials. Then through strict quality regulation and specific process requirements, the frame of the flat die pellet making equipment we produced is durable and qualified.In addition, in order to facilitate transportation, we set hoisting holes in the middle of the four corners of the frame.

Breaking And Separating Part

After be pressed by the rollers in the flat die pellet machine, the based fertilizers will be into the breaking device. There is double-axis mace equipment in the breaking area. You can separate the spherical material and the return material through this equipment. På denne måde, you can improve the working efficiency of the granular fertilizer production lines.

Transmission Connection Part

The transmission connection part is an important part of the flat fie granulation When the transmission connection parts are working, the electric motor will drive the pulley, V-belt, and reducer to rotate. Driven by these parts, the flat die granulator starts to granulate the fertilizer materials. Derudover, there is a transmission chain composed of sprocket and chain on the transmission connecting part, which is the main motivation for driving the working part of the crushing and separating part. For the transmission reducer and the head working part, we use the mutual work of the nylon pin coupling to transmit the drive.

The Head Working Part

Som nævnt ovenfor, the power of the working part of the machine head is transmitted from the transmission wheel to the transmission roller through the pin shaft. We use a pair of open wheels to ensure that the pair of rollers are synchronized. Derudover, both sides of the active and passive shafts are composed of specific bearings and bearing frames, which are finally installed on the frame.

Fra ovenstående, you can know more about the structure of the SX flat die granulation machine. With such structural design, the working efficiency and the service life of the machine will be increased. That is why so many fertilizer makers highly praise the flat die pellet making machine produced by SX.

How Does The Flat Die Granulator Process The Fertilizer?

If you want to buy the high-quality flat die granulation machine, in addition to know the machine structure, you also need to have intimate knowledge of working principle. The followings are the detailed working principle of the flat-die granulation machine .

With the continuous rotation of the motor on the transmission connection part and the continuous addition of materials, you can batch produce fertilizer particles and improve the efficiency of the fertilizer particle production line.

How To Adjust The Flat Die Granulator?

When you find that there is not an ideal granulation effect by using the flat die pellet machine. You need to adjust the granulation machine properly currently. What part do you need to adjust? You can adjust the flat die granulation machine according to the following methods.

If you want to improve the granular fertilizer productivity or increase the nip angle, you can increase the gap between the Driving shaft roll and driven shaft. Derudover, you should note that the two rollers are not allowed to contact. You should keep a gap of 0.3mm-1 mm between the rollers.

For flat die granulation machine, the adjust method of ball socket is like that of double-roller extrusion granulator. When adjusting the ball and socket of these two granulators, you need to adjust them from the circumferential and axial directions.

Through the above method, you can adjust the flat die granulation machine according to the production requirements. By adjusting, you can improve the working efficiency of the flat-die pellet making machine.

You know that the SX flat die granulation machine is popular with the manufactures of organic fertilizer and compound fertilizer. Hvad mere er. SX can provide you with many special services like technical support, on-site installation and customized service. Derfor, while purchasing the flat die granulator, you can contact us for the detailed information,