You should consider the $550,000 organic fertilizer production line price from three aspects. They are the fertilizer production line design, organic fertilizer type and production equipment selection. The following are about them.

Based on the above three problems, there are some experience to share with you. The following can be your reference.

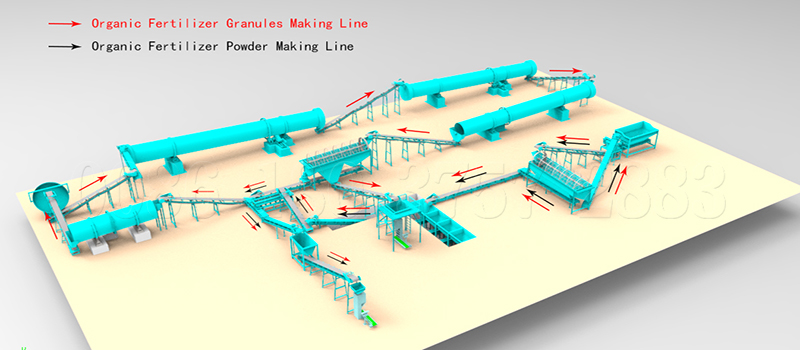

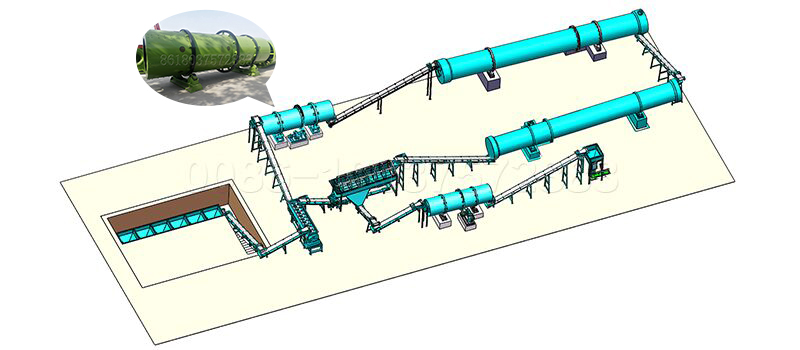

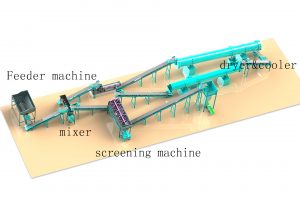

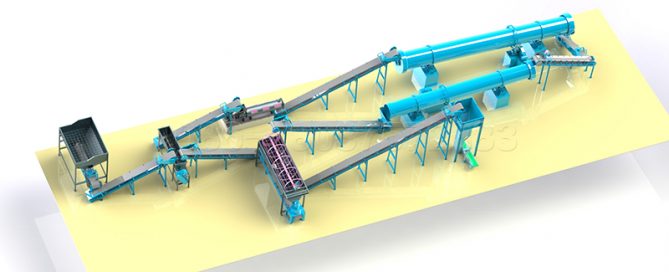

The machines used in $550,000 organic fertilizer production line

Compost turner machine, compost shredder, rotary screeing machine, fertilizer granulator machine, drum drying machine, cooling machine, granular coating machine and granualr packing machine.$550,000 Organic fertilizer production line

Five Aspects Will Affect $550,000 Organic Fertilizer Production Line Price.

If you manage the organic fertilizer with the budget of $550,000, there are five factors you need to notice. You can know about the specification from the followings.

By doing the above mentioned, you will have the comprehensive considerations for managing the $550,000 organic fertilizer production lines.

The Organic Fertilizer Producing Technology You Can Adopt Within $550,000

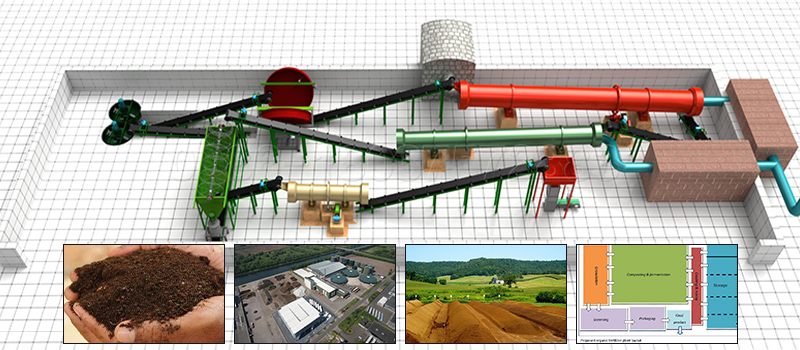

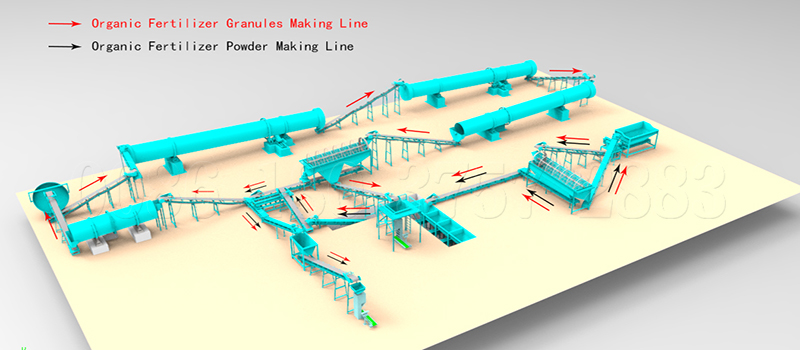

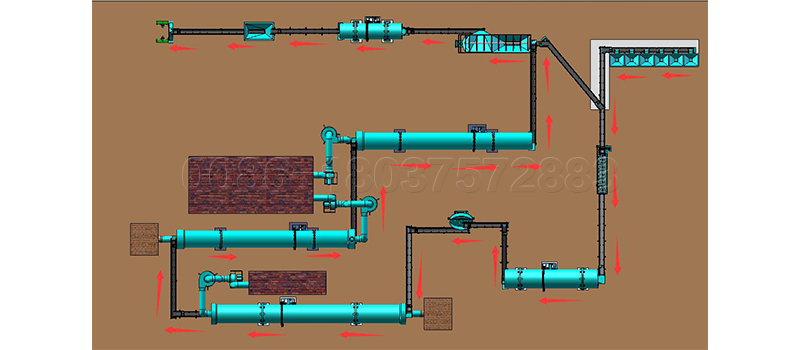

Kā minēts iepriekš, you will know the importance of selecting the right organic fertilizer production lines. Considering that you want to make the organic fertilizer production lines with the budget of $550,000, we recommend that you produce the organic fertilizer granules. What is the specific production process of the granular organic fertilizer? You can learn about the production process from the followings. There are three stages of the granular organic fertilizer production process.

While Granulating

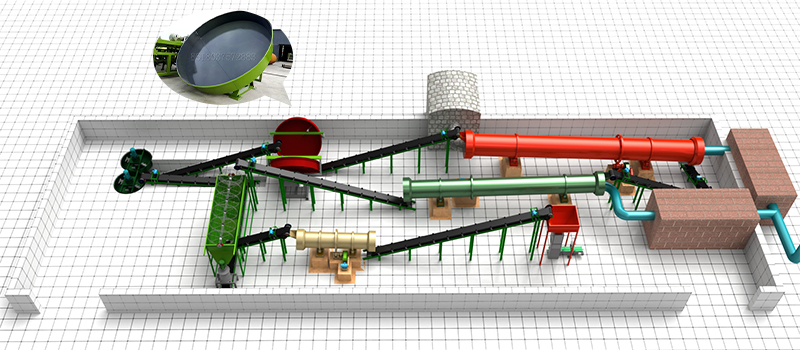

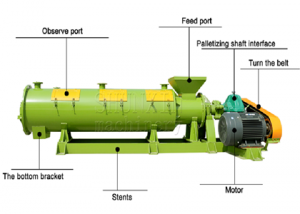

After the preparation stage, you can deliver the powder organic fertilizer into the granulation machine for granulating. In order to get the high ball forming rate and high-quality fertilizer particles, we suggest that you use SX granulation machine. As for the $550,000 granular organic fertilizer production lines, you can select the rotary drum granulation machine and the disk granulator.

Drying And Cooling

There are two problems about the organic fertilizer granules after the granulation process. One is organic fertilizer granules moisture. The other is the organic fertilizer granules strength.You should dry and cool the organic fertilizer particles to increase the strength and lower the nutrients loss. when you need to buy the žāvēšanas mašīna and cooling machine, you can consider to use the SX rotary drum cooling machine and the drying machine.

Screening.

Then you need to screen the organic fertilizer granules again. You should sent the unqualified particles back to the granulating process. As for the qualified granules, you need to coat them by using the coating machine.

Coating.

Mēslojuma granulu kvalitātes uzlabošanai, the fertilizer makes will coat the pellets. After being coated, the organic fertilizer grinds will not be blocked during the storage and transportation.

For managing the $550,000 organic fertilizer production lines, you can choose many types of the production equipment. Lai arī, you can consult us for designing the beat plan of the organic fertilizer production. Papildus, we can recommend the most proper machines for you according to your budget.

What Materials Can You Collect For The $550,000 Organiskā mēslojuma ražošanas līnijas?

You can use many kind of the raw materials to make the organic fertilizer. Lai arī, what materials can you choose for your $550,000 organic fertilizer production lines to make the high-quality fertilizer? Tāpēc, you can select raw materials from the following two sources.

The Animal Waste

There are many kinds of nutrients in animal feces. Piemēram, in poultry manure, the content of organic matter is about 25%. There are 1.63%N, 1.5%P2O5, 0.85% K2O in the poultry manure.However, when making the organic fertilizer from the animal manure, you should compost the manure completely. Otherwise, the harmful bacteria will affect the crop growth.The Agricultural Waste

Agricultural waste is an agricultural by-product, a useful resource. Vēl vairāk, it is one of the indispensable raw materials for making organic fertilizer. Piemēram, the content of organic matter in the straw of crops is 15%. Of course, it also contains calcium, magnesium, sulfur and other important trace elements. These are all essential nutrients for the growth of crops.Both animal manure and agricultural waste can be used for producing the organic fertilizers. You should note the compost process when using them to make the fertilizers.

Raw Material Supplier Selection At The Best $550,000 Organic Fertilizer Production Line Price?

When you choose the raw materials supply location, there are two factors you need to consider. One is the distance between the production sites and supply location. The other is the production formula. You can know about the specification from the following.

The Distance

In order to lower the transport fee of the raw materials, you need to choose the supplier which is near the production plant. Because, generally speaking, the raw materials of the organic fertilizer are the organic waste such as animal waste un lauksaimniecības atkritumi. It is difficult for you to transport such materials. Tāpēc, you should the supplier near the factory. You can also build the organic fertilizer plant near by the place of supplying the raw materials. To darot, you can save the production cost and keep the raw materials quality.

The Formula

The formula determines what kinds of the raw materials you can choose. When you choose the materials based on the scientific formula, you can making the organic fertilizer with high quality and adequate nutrients. Then the organic fertilizer you produce will have the strong competitiveness.

After considering these two aspects, not only can you reduce the cost of running the $550,000 organic fertilizer production lines, but also you can make more benefits from producing the organic fertilizer.

How To Choose Production Facilities For $550,000 Organic Fertilizer Production Line At Fair Price??

There are many types and specifications organic fertilizer production equipment at home and abroad. Lai arī, how to choose the right machines for your $550,000 organic fertilizer? You can consider this question from the following two aspects.

In some way, the working efficiency of the organic fertilizer production machines is related to its composition materials. Tāpēc, when you buy the machines, it is very necessary to check the composition materials. The high-quality production equipment should be equipped with the composition materials which have the characteristics of wear resistance ans corrosion resistance. Piemēram, the rotary drum granulation machine produced by SX has a stainless steel or rubber lining inside the machine. The lining can avoid the materials corrosion effectively.

The machine working efficiency determines the production capacity of your organic fertilizer production lines. When managing the $550,000 organic fertilizer production lines, you need to buy the high productive equipment to improve the productivity. For different productivity of organic fertilizer production line, our company has produced equipment with different work efficiency. Piemēram, for your $550000 organic fertilizer production line, we have the SXZGZ-3210 rotary drum granulation machine with the productivity of 15-50 t/h.

Through following the above two aspects, you will choose the right fertilizer production machines. Papildus, you will experience the fair $550,000 organic fertilizer production line price.

How To Choose The Organic Fertilizer Equipment Producer With The Budget Of $550,000?

In order to get the organic fertilizer with high working efficiency, you should choose the right supplier. But how to choose the most suitable one among many organic fertilizer equipment producers? You can select the organic fertilizer equipment supplier from the following advice.

As a supplier of years of experience in organic fertilizer equipment production, we are guaranteed to provide you with high quality machines at a fair price. Papildus, you will experience our top class service throughout the purchase process. Our technicians will provide you with on-site installation or guidance services.

What is the Granular Organic Fertilizer Production Line Price?

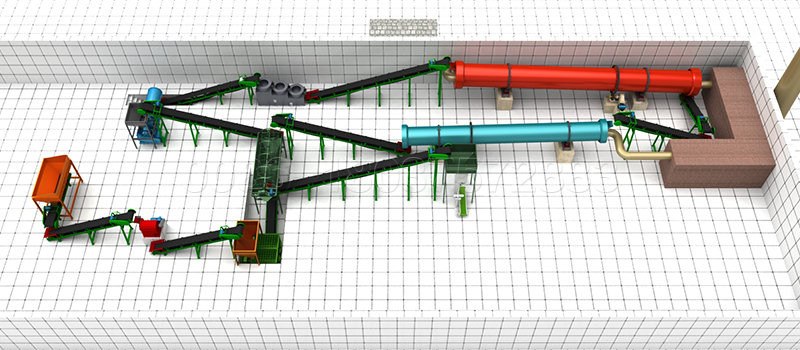

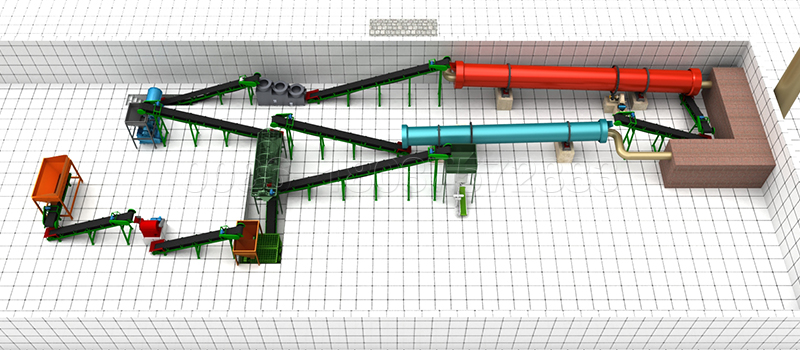

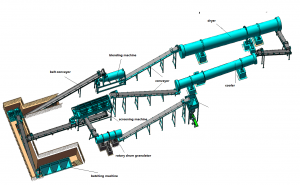

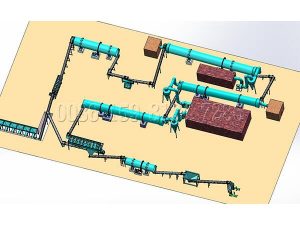

The granular organic fertilizer production line prices is related to its configuration. For customers with different budgets, FPC designs and produces different configurations of organic fertilizer granules production lines. We can divide the organic fertilizer granulation lines into two types. One is organic fertilizer stirring tooth granulation line, the other is rotary drum and disc granulation line. You can get their configurations and prices from the following.

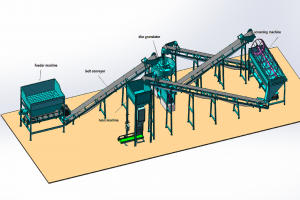

Stirring tooth granulation line for small&medium organic fertilizer plant

Stirring tooth granulation line is an new type granular organic fertilizer production line. The fertilizer manufacturer with budget of $110,000-$190,000 can get one complete set of stirring tooth granulation line. The customers can produce 1-5 tons organic fertilizer pellets per hour. Tāpēc, it more suitable for small to medium fertilizer plant. When purchasing this line, you need to deploy a wheel type compost turner, SXFLF-600 vertical type compost shredder, SXGS-1540 rotary screening machine, SXJZ-1200 stirring tooth granulator, mēslojuma pārklāšanas mašīna and other auxiliary fertilizer making machines. The equipment manufacturer will also recommend best model of machines for you.

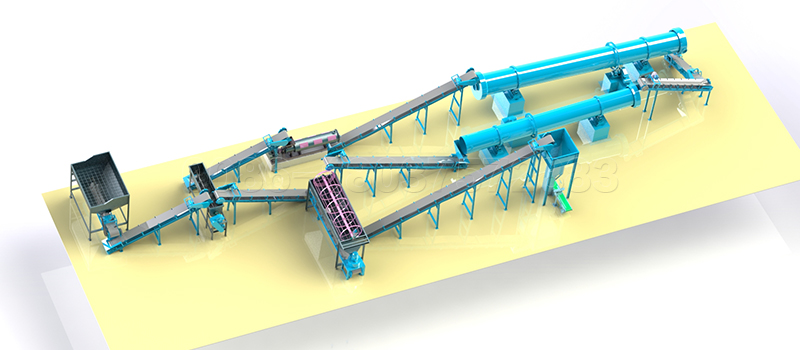

What is the drum and pan organic fertilizer granulation line price?

This production line has higher production capacity than the above new design organic fertilizer granulation line, about 10t/h-20t/h. it is widely used in large scale organic fertilizer manufacturing plant. Papildus, its price is also higher than the above production line. You can get this whole line with the price of $360,000-$550,000. As like its name, the production line equips two types of fertilizer granulators. They are disc granulator un rotācijas cilindru granulators. According to its yield, you should buy SXFLF-1000 vertical type crusher, SXGS-2080 rotary sieving machine and high yield of auxiliary machines. When installing this line, you need to prepare a 5000-10000 square meters of production site.

For organic fertilizer manufacturer customer with the budget of $550,000, we recommend you to buy the second production line. You can get the returned profits quickly after running the drum and disc granulation line. Vēl vairāk, you can get the organic fertilizer granules with more beautiful appearance. That is because the fertilizer are granulated twice. If you want to buy a granular fertilizer production line, contact us. You will get the best design solution of organic fertilizer granules production line. Papildus, you can get the latest organic fertilizer making machines price list. Welcome to inquiry.

The above is about how to set up the organic fertilizer production line with the budget of $55,000. When managing the organic fertilizer manufacturing business, Jūs varat sazināties ar mums. We will provide you with the further information about the fertilizer production project. Turklāt, you will get the best $550,000 organic fertilizer production line price from SX.