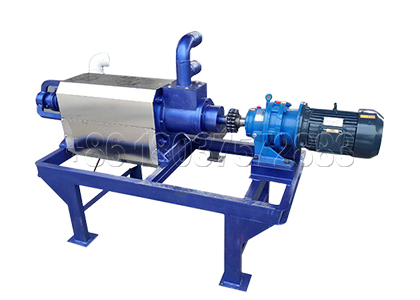

Cow dung is an important raw material source to make the bio organic fertilizer. There are two main methods for cow manure disposal. Első, you can compost the cow manure for powder organic fertilizer production. The second one is to make the cow manure bio organic fertilizer pellets. Ráadásul, you can make fully use of the cow manure waste water to make organic liquid fertilizer after dewatering. For making bio organic fertilizer, FPC produces many kinds of fertilizer equipment for cow dung treatment,such as solid-liquid separator, komposztáló gép, granulator equipment and other auxiliary machines. From the following, you can know more about the cow dung bio organic fertilizer production technology and machines needed during the production.

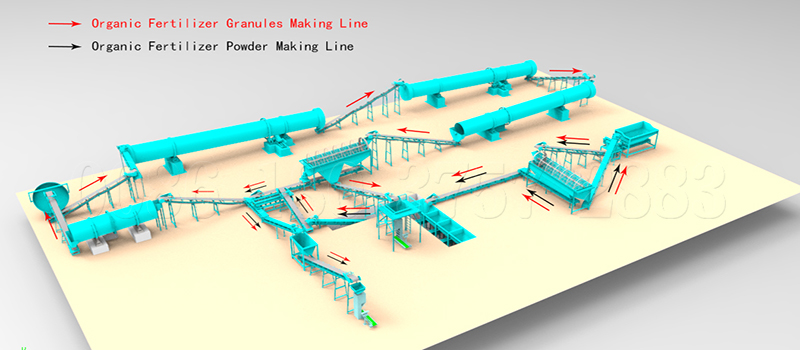

There are two types of cow manure bio organic fertilizer production process you can select. One is powder cow manure biological fertilizer manufacturing process. And the other is granular cow dung bio-organic fertilizer production process. The former will be cost less than the latter. Viszont, the economic benefit of granular fertilizer is higher than that of powder cow manure fertilizer. Customers can choose the best production process of cow dung bio-organic fertilizer based on budget and production plan. You can know the detailed manufacturing process from the following.

What is powder cow dung bio organic fertilizer production technology?

As we all know, the cow dung can become quality bio organic fertilizer after mixing with some auxiliary materials like crop straw. Let’s learn about how to make the powder bio organic fertilizer from cattle manure. There are six steps for cow manure bio organic fertilizer production. They are dewatering, keverés, composting, crushing, screening and packing. You can know the detailed manufacturing process from the following.

The above is about the powdered cow manure bio fertilizer production technology. FPC designs and produces the cow dung powdery line with different production capacities. You can contact with us to buy the customized cow dung powder production line. The following will introduce the three mechanical composting methods for cow manure disposal to you.

How to make powder cow dung compost into bio-organic fertilizer pellets?

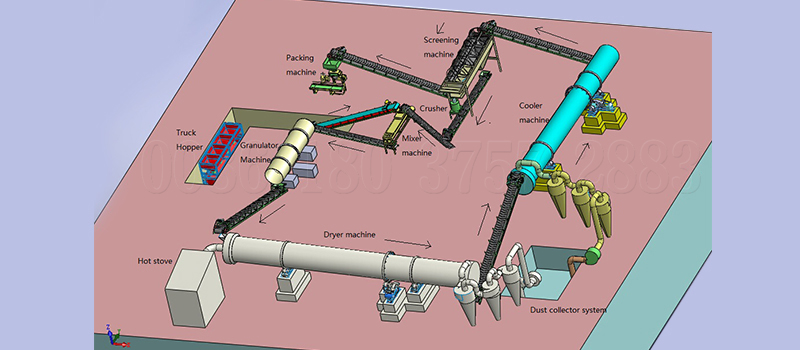

After composting, the powder cow manure can be turned into granules to improve its market price. There are five steps for making biological cow dung fertilizer granules. They are granulation, szárítás, hűtés, screening and packing. In order to manufacture the cow manure pellets efficiently, you need to purchase a complete set of fertilizer pellet production line. You can know about the complete cow manure bio organic fertilizer granules production process form the following.

The above is the production process of cow manure granules. There are complete sets of fertilizer equipment for cow manure granules production in FPC fertilizer equipment company. All of them are on sale at favorable price. You can contact with us for the newest quoted price list. Mi több, you can get the customized service from us. We can customize the cow manure powder line and granulation line based on your production capacity and budget.

What Key Production Machines Are Used in Cow Manure Bio Organic Fertilizer Production?

Whether to produce the granular fertilizer or powder fertilizer, there are some indispensable machines. When making the powdery bio organic fertilizer, you must use the fermentation machine to make cow manure composting smooth. While producing the biological fertilizer granules, you should use the fertilizer granulator machine to form cow manure balls. Majd, what fermentation or granulator machine is the most suitable for your production line? The following can be as your reference.

What fermentation equipment required for cow dung bio organic fertilizer production?

A fentiekből, we know that you can use the groove type compost turner, windrow compost turner machine and in-vessel composting machine to treat the cow manure. They are available in different fermentation production site. You can buy them according to fertilizer production area and budget. A következő lehet a referencia.

Groove type fermentation machine

Rail type compost turner, chain plate type compost turner and wheel type composting machine are groove type fermentation machine. They are used in conjunction with the fermentation groove. Ezért, you should build composting troughs in advance. Before composting, you need to place the cow manure into the compost pit. After that, you can ferment the cow manure with groove type composting machine. The groove type fermenting machines have the advantages of less production area, high turning depth (0.8m-2.5m), quick temperature rise. It is more suitable for scale production plant.

Windrow type composting machine

When using the compost windrow turner, you should pile the cow manure into long strips with certain height. Ezért, you should prepare larger production area for composting. After cow manure stacking, you can operate the compost windrow turner to ride on the materials piles for turning. The windrow compost turner machine is more suitable for sticky raw materials disposal. You can buy crawler type windrow turner and movable compost turner when applying windrow composting. Viszont, what you need to note is the windrow composting effect is affected by seasons and weather easily.

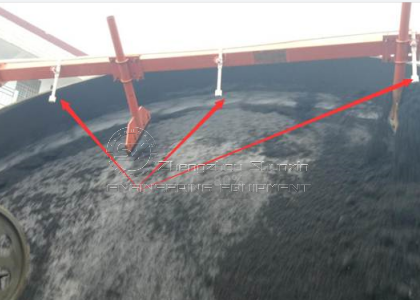

In-vessel composting equipment

The fermentation tank is in vessel composting machine which is widely used in organic fertilizer plant. After the cow manure pre-treatment, you can put the cow manure into the fermentation pot for composting. The fermentation process of the manure is fully automatic. FPC fermentation tank can control different stages precisely during the fermenting process. Mi több, it can operate normally at cold and hot seasons. Because of short fermentation cycle and small required production area, the fermentation tank is popular with the large scale organic fertilizer manufacturing factory.

Through the above mentioned, you will get a further understanding about these three types of cow manure composting machines. FPC organic fertilizer equipment manufacturer has dedicated in compost turning machine design and production over 15 év. Ezért, you can buy the above three kinds of turning compost machine at best price in FPC.

How to choose the right cow manure granulator machine for biological fertilizer production?

There are many types of granulator machines in the fertilizer equipment market. To make the cow manure bio organic fertilizer pellets, there are three types of recommended fertilizer granulator machine for you. They are new type organic fertilizer granulator, disc granulator and rotary drum granulator. The followings are the detailed information about these three types of granulation machines.

New type organic fertilizer granulator

It is a pelleting equipment which makes the 2-5mm fertilizer balls under the action of mechanical agitating force. The biggest advantage of the churning granulator is that it can completely retain the bio organic matter in the cow manure. Ezért, it is one of the most popular granulators of fertilizer manufacturer. The churning granulation machine made from FPC is a hot-selling product. That is because that FPC stirring tooth pelletizer takes some special designs like visible windows and replaceable stirring teeth head. All of them are designed for efficient granulation process. You can visit our website to get its detailed description.

Rotary drum granulator

The rotary drum pelletizer is more suitable for the large scale organic fertilizer granules production line. The drum granulation machine manufactured from FPC company can produce 1-30 tons fertilizer pellets per hour. Mi több, its granulation rate can up to over 90%. In order to improve machine utilization, we set the stainless steel or industrial rubber inner lining inside rotary drum pelletizer. The inner lining can protect the drum granulator from corrosion and wear to prolong its service life. There are many models of drum pelleting machine you can choose from in FPC.

Pan granulator

Disc granulation machine is a kind of wet granulator. You need to spray the water into the disc when using it for cow manure bio organic fertilizer production. FPC pan pelleting machine is equipped with an automatic liquid spray device. The device will save the manpower for you. Ráadásul, you can also adjust the cow manure biological fertilizer pellet size through regulating water spray device. Általában, FPC disc granulation machine can produce1-8mm fertilizer pellets. Mi több, the granulation time is also short, about 5-6min. Viszont, its production capacity is lower than the churning granulator and rotary drum granulator. You can assemble a set of double pan granulation line to improve the fertilizer pellets yield. There are whole disc granulation lines with different configurations and production capacities for sale in FPC.

The above three kinds of fertilizer pelletizers are in stock in FPC organic fertilizer equipment company. They are on sale at the best price. You can also find some dry granulator like flat die granulator and double roller extrusion pelletizer. Mi több, we produce different models and technical parameters of these fertilizer pellet making machines.Therefore, you can buy the ideal fertilizer granulation machine at the best cost in FPC company.

How Much Does the Cow Manure Bio Organic Fertilizer Production Cost?

The cost of cow feces bio organic fertilizer production changes as the produced fertilizer types and production capacity. Based on different production capacities, we divide powder or granular cow manure bio organic fertilizer production line into multi types. All of them are on sale at different price. You can buy ideal cow manure biological organic fertilizer production line according to your budget.

What is the cost of powder cow dung organic fertilizer production line?

Cow manure bio organic fertilizer powder line cost is related to the capacity and machine configuration. Kis és nagy műtrágyagyártóknak, we design and produce the cow dung fertilizer powder line with various production capacities. 1-3t/h, 5-10t/h,10-20t/h. Az eltérő hozamok miatt, a porsort különböző típusú és műszaki paraméterekkel rendelkező műtrágyaberendezések telepítik. The price of FPC cow manure powdery fertilizer production line ranges from $35,000-$90,000. A gyártósor részletes kialakítását és árát az alábbiakból ismerheti meg.

1-3t/h cow manure powder line

The whole set of 1-3t/h cow manure powder fertilizer production line is worth about $35,000. Azok a gépek, amelyeket be kell helyezni, a hornyos komposztforgató, SXSF-60 félnedves anyagzúzó, SXSJ-0830 kéttengelyes vízszintes keverő,SXGS-1030 rotary drum screening machine and powder packing machine. Ráadásul, vásárolnia kell néhány szállítószalagot a por szerves trágyagyártás minden részének csatlakoztatásához. Fel kell készülni 800 négyzetméter ( körülbelül 0.198 acre) a teljes gyártósor telepítéséhez. The 1-3t/h cow manure powder line is more suitable for small fertilizer manufacturer with less cow manure or low budget.

| Modell | 1-3t/h cow manure powder line |

|---|---|

| Költségvetés | $35,000 |

| Konfiguráció | horony típusú komposztforgató, SXSF-60 félnedves anyagzúzó, SXSJ-0830 kéttengelyes vízszintes keverő,SXGS-1030 forgódobos szűrőgép, por csomagoló gép,szállítószalag és így tovább |

| Occupied land area | 800 négyzetméter ( körülbelül 0.198 acre) |

| Modell | 5-10t/h cow manure powder production line |

|---|---|

| Költségvetés | $45,000-$60,000 |

| Konfiguráció | gwheel type compost turner machine , SXFLF-800 függőleges típusú komposzt aprító gép, SXSJ-0830 kéttengelyes vízszintes keverő, SXGS-1030 drum sieving machine and powder packing machine, szállítószalag és így tovább. |

| Occupied land area | 1500-3000 négyzetméter (0.37-0.74acre) |

5-10t/h cow manure powder production line

The configuration of this powder line is higher than that of 1-3t/h cow manure powder line. Ezért, meg kell vásárolnia a nagy gyártóberendezéseket a telepítéshez 5-10 tonna/óra teljesítményű műtrágya gyártósor. You’d better buy the wheel type compost turner machine for cow manure fermentation. A zúzási folyamathoz, az SXFLF-800 függőleges típusú komposzt aprító gép lesz a jobb választás. The SXGS-1560 drum screening machine replace the SXGS-1030 drum sieving machine. A termelési hely területét, amelyet fel kell készítenie: 1500-3000 négyzetméter (0.37-0.74acre). The production line is more suitable for organic fertilizer producers with more cattle waste and adequate budget.

10-20t/h powder cow manure production line

10-20tons per hour powder cow manure production line is mostly used in fertilizer manufacturer with more raw materials and higher yield. termelni 1 tonna kész szerves trágyát igényel 3 tonna nyersanyag, tehát előállítani 10-20 tonna porított bio-szerves műtrágya óránként, fel kell készülnie 30-60 tons of cow dung raw materials. Egy időben, az Ön gyártósorát is fel kell szerelni megfelelő gyártási kapacitással rendelkező szerves trágya gyártó berendezéssel. A por gyártósor magasabb konfigurációja miatt, sokkal több pénzt fogsz költeni rá kb ($60,000-$90,000).

| Modell | 10-20t/h powder cow manure production line |

|---|---|

| Költségvetés | $60,000-$90,000 |

| Konfiguráció | lánctalpas típusú komposztforgató gép , SXFLF-1000 függőleges típusú komposzt aprító gép, SXWJ-1630 vízszintes keverő, SXGS-2080 dobszűrőgép és porcsomagoló gép, szállítószalag és így tovább. |

| Occupied land area | 3000-5000 négyzetméter (0.74-1.25acre) |

The above are 1-3t/h,5-10t/h,10-20t/h powder cow manure fertilizer production line price and required machines. Az adatok csak tájékoztatásul szolgálnak. A szerves trágyapor vonal tervezési megoldását módosítjuk az ügyfél költségvetésének és hozamának megfelelően. You can also buy the customized cow manure powder line from us. Kérjük, lépjen kapcsolatba velünk, és mondja el szerves trágya gyártási tervét.

How much is the granular cow manure bio organic fertilizer production line?

The price of the cow manure granules production line is higher than powder one. That is because that the granular cow manure bio organic fertilizer is further produced based on the powder fertilizer. You should deploy more fertilizer equipment for making cow manure fertilizer pellets than that of powder cow manure production. The granular cow manure fertilizer production line budget is also related to the yield and deployed machines. We can divide the granular cow manure bio organic fertilizer production line into two types according to the yield. Az egyik az 1-5 tonna/óra szemcsés műtrágya gyártósor, a másik pedig 10-20t/h műtrágyagranulátum gyártósor. Különböző áron kaphatók. A konkrét árat és a géptelepítést az alábbiakból kaphatja meg.

The 1t/h-5t/h cow dung fertilizer granulation line is worth about $110,000-$190,000. The cow manure pellet production line is more suitable for medium and large scale organic fertilizer plant. Ennek az 1-5t/h műtrágyagranuláló sornak a vásárlásakor, you should prepare 2000㎡-4000㎡ (körülbelül 0.5-1 acre) gyártóhelyen a teljes gyártósor telepítéséhez. Ezért, több pénzt fog költeni a gyártóhely építésére. Kívül, A megvásárolandó műtrágyagépek új típusú szerves trágya granulátorok, dobszárító, dobhűtő, műtrágyabevonó gép, műtrágyaszűrő gép és szemcsés műtrágya csomagoló gép. Így, több pénzt kell előkészítenie, mint $110,000-$190,000 ennek a gyártósornak a működtetéséhez.

| Modell | 1-5 t/h cow manure granular fertilizer production line |

|---|---|

| Költségvetés | $110,000-$190,000 |

| Konfiguráció | komposztforgató gép , SXSF-120 félnedves anyagú komposzt aprítógép, SXWJ-9015 vízszintes keverő, új típusú szerves trágya granulátor, dobszárító, dobhűtő, fertilizer coating machineSXGS-1240 drum sieving machine and granular fertilizer packing machine, szállítószalag és így tovább. |

| Occupied land area | 2000㎡-4000㎡ (körülbelül 0.5-1 acre) |

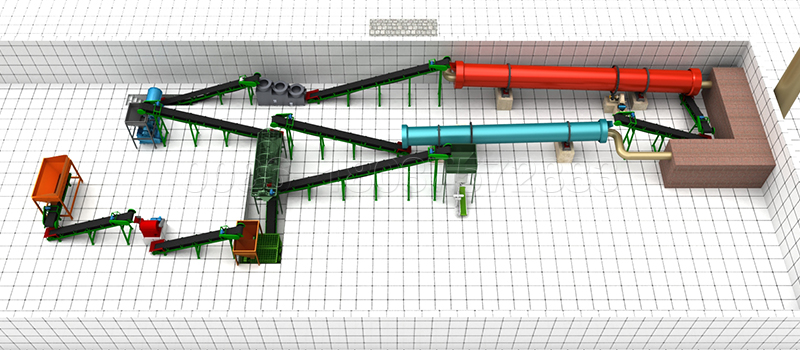

A teljes 10-20 tonna/óra granulálósor ára tól $360,000-$550,000. A teljes sor konfiguráció magasabb, mint az 1-5 t/h műtrágyagranuláló soré. Ezért, you should prepare larger production site for complete 10-20t/h cow manure granules production line (about 5500-10000㎡, 1.4 hektár-2,5 hektár). A gyártósor nagyüzemi műtrágyagyártónál kapható. Ráadásul, inkább cserélje ki a keverőfogas pelletálót serpenyős granulátorra és forgódobos granulátorra. Ez nem csak a gyártósor teljesítményét fogja növelni, hanem csökkenti az energiafogyasztást is.

| Modell | 10-20 t/h cow manure fertilizer granules production line |

|---|---|

| Költségvetés | $360,000-$550,000 |

| Konfiguráció | komposztforgató gép , SXSF-120 félnedves anyagú komposzt aprítógép, SXWJ-9015 vízszintes keverő, serpenyős granulátor, forgódobos granulátor,dobszárító, dobhűtő, fertilizer coating machineSXGS-1240 drum sieving machine and granular fertilizer packing machine, szállítószalag és így tovább. |

| Occupied land area | 5500-10000㎡, 1.4 hektár-2,5 hektár |

How do we design 500kg/h cow manure bio organic pellet production line for Pakistan customer?

FPC is an established organic fertilizer equipment production company. Our organic fertilizer production lines have been sold all over the world, such as India, the US, Argentina and other countries. Here is an successful case that we design the 500kg/h cow manure granules production line for Pakistan fertilizer manufacturer. You can know the detailed process from the following.

The above is a part of communication process about 500kg/h cow manure granules production line design. You can also get the customized organic fertilizer pellets production line from us. Contact with us, tell us your raw materials and production capacity. We will provide you with the best animal manure fertilizer production line.

A fentiekből, you can get the further standing about the cow manure bio organic fertilizer production process. Az adatok csak tájékoztatásul szolgálnak. You can email to us for detailed consultation. FPC company has been engaged in organic fertilizer production line design, production and installation for many years. We have the confidence to offer you quality and efficient fertilizer production line and equipment. Mi több, our organic, inorganic, compound fertilizer production line and machines are on sale at the favorable price. Contact us to get the newest quoted price list.